Steel plate cutting machine is a kind of mechanical equipment widely used in the cold rolling industry.

It can cut steel plates efficiently, accurately, and beautifully. However, the performance and quality of a steel plate cutting machine depends not only on the cutting machine itself but also on an often overlooked component – the felt tension pad.

What is a felt tension pad?

What are its functions and advantages?

How do you choose and maintain felt tension pads?

This article will answer them one by one for you.

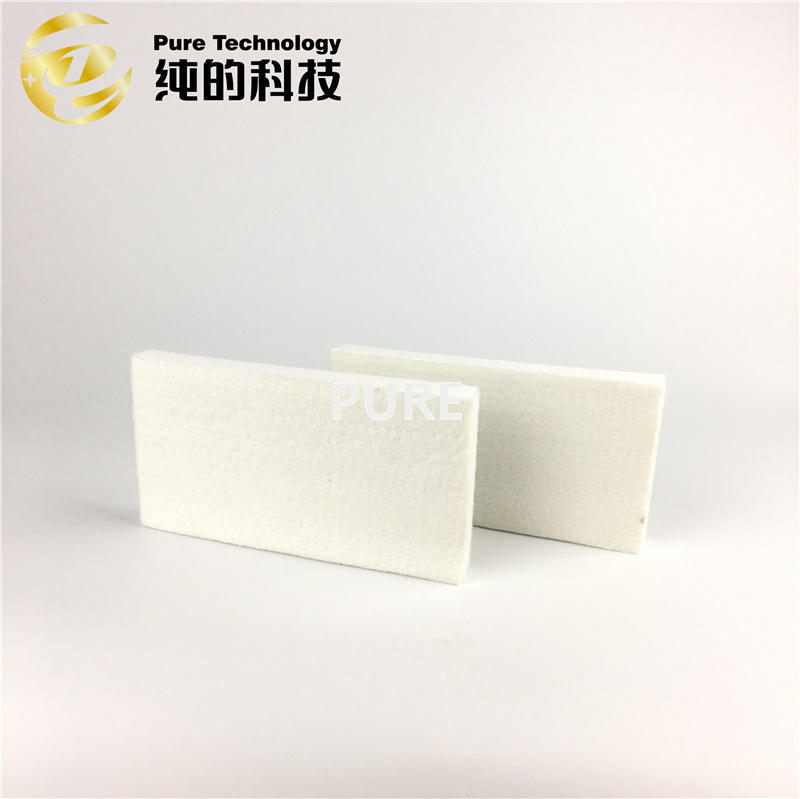

The felt tension pad is a circular gasket made of high-temperature and wear-resistant industrial felt.

It is installed on the tool holder of the steel plate cutting machine and contacts the steel plate to buffer, protect, and increase friction.

(1)It can effectively reduce the heat generated during steel plate cutting and prevent steel plate deformation and damage.

(2)It can effectively absorb the vibration generated during steel plate cutting and improve the stability and accuracy of cutting.

(3)It can effectively increase the friction between the steel plate and the tool holder to prevent the steel plate from sliding and deflecting.

(4)It can effectively protect the knife holder and blade and extend their service life.

It can be seen that the tension pad is an indispensable and important part of the steel plate cutting machine, which directly affects the effect and quality of steel plate cutting.

Choosing the appropriate tension pad is the key to ensuring the normal operation of the steel plate-cutting machine and extending its service life.

(1)Material: The material of the felt tension pad should have the characteristics of high-temperature wear resistance.

High strength, high density, high elasticity, etc.

It is generally made of industrial felts such as polyamide fiber (PA) or polyimide fiber (PI).

These materials can maintain good physical properties and chemical stability in high-temperature environments and are not easy to melt, burn, deform, or delaminate.

(2)Specifications: The specifications of the tension pad should match the tool holder of the steel plate cutting machine.

Which is generally determined based on the diameter, thickness, aperture, and other parameters of the tool holder.

If the specifications are inappropriate, it will affect the firmness of the installation and the effect of use.

(3)Performance: The performance of the felt tension pad should meet the working requirements of the steel plate cutting machine.

Generally, the following indicators must be considered: wear resistance, temperature resistance, shock absorption, friction coefficient, etc.

These indicators can be judged through experiments or data provided by the manufacturer.

If the performance is not up to standard, the life of the tension pad will be shortened or the quality of the cut will be reduced.

In addition to the above aspects, you also need to pay attention to choosing regular brands and suppliers to ensure the quality and after-sales service of the felt tension pads.

We are a manufacturer specializing in the production and sales of felt tension pads for steel plate cutting machines.

We have many years of industry experience and technical advantages.

(1)We adopt advanced technology and equipment to ensure the uniformity and stability of the tension pad and avoid the problems of local hot spots and stress concentration.

(2)We use high-quality raw materials and additives to improve the wear resistance, temperature resistance, and antistatic properties of the felt tension pad, and extend its service life.

(3)We have adopted a strict quality control and testing system to ensure that every piece of tension pad meets international standards and customer requirements and is free of defects.

Maintaining the felt tension pad is a necessary condition to improve the working efficiency and quality of the steel plate cutting machine.

(1)Cleaning: Regularly use a soft cloth or soft brush to remove dust, oil, and metal shavings.

And other debris on the surface of the felt tension pad to keep it clean and dry.

Avoid cleaning with water or other solvents as this may affect its performance.

(2)Inspection: Regularly check the wear, deformation, looseness, etc. of the tension pad.

And observe whether there are cracks, delamination, scorching, and other damages.

If abnormalities are found, they should be processed or replaced in time.

(3)Replacement: According to usage conditions and manufacturer’s recommendations.

Replace new felt tension pads regularly, usually after a certain period of use or after cutting a certain number of steel plates.

(4)When replacing, you should pay attention to turning off the power and removing the old felt tension pad.

Installing the new felt tension pad, and ensuring that it fits tightly with the tool holder without gaps or looseness.

(5)Adjustment: According to the thickness and hardness of the steel plate, adjust the pressure between the tension pad and the steel plate so that it can not only ensure the accuracy and quality of cutting but also reduce the loss of the felt tension pad.

When adjusting, attention should be paid to balancing the pressure on both sides to avoid unevenness or deflection.

Through the above steps, the service life of the felt tension pad can be effectively extended and the working efficiency of the steel plate cutting machine can be improved.

(1) The steel plate is cut unevenly, with defects such as cracks, chips, and chamfers appearing.

(2) The steel plate cutting is not accurate, and problems such as dimensional deviation and angle error occur.

(3) The steel plate is not beautiful when cut, with scratches, oxidation, stains, etc. appearing.

(4) Steel plate cutting is unsafe, and there are dangers such as sparks, splashes, and jamming.

(1) Choose a suitable tension pad, check its status regularly, and replace damaged felt tension pads promptly.

(2) Adjust reasonable pressure and speed, maintain a stable cutting state, and avoid excessive pressure, friction, and heat.

(3) Clean the surface of the steel plate and maintain good contact between the steel plate and the felt tension pad to avoid contamination, sliding, and deflection.

(4) Use high-quality blades and check their sharpness regularly to avoid using dull, deformed, or damaged blades.

The above are some common problems and solutions for felt tension pads that I have written for you. I hope they will be helpful to you. If you have any other questions, please feel free to communicate with me at any time.

If you have any questions, you can also watch our Facebook website:www.facebook.com/nomexfelt

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The aluminum extrusion machine is the leading equipment for the production of aluminum profiles. ...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

What is Nomex? Meta-amide, or meta-phenylene isophthalamide, is made from meta-phenylenediamine a...

Kevlar fiber Introduction In the development of materials science, Kevlar fiber has particularly ...