product

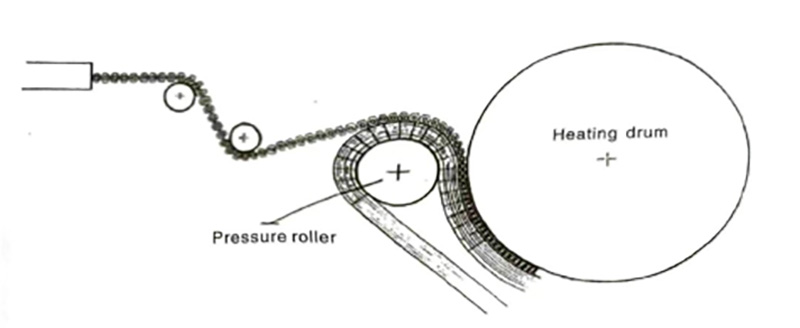

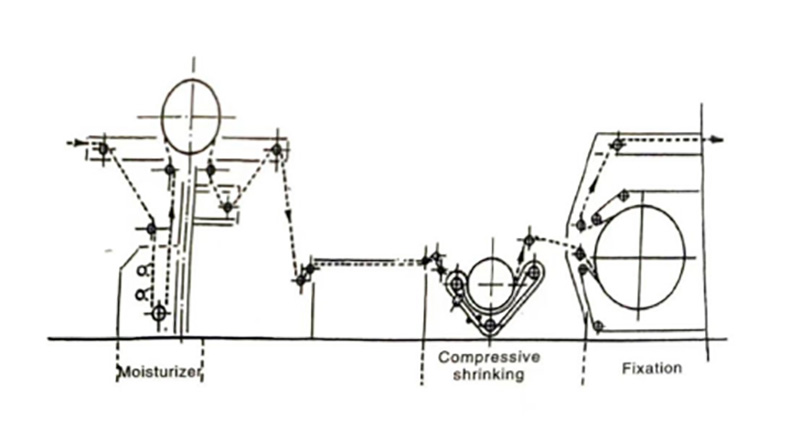

It is used in the finishing process of the fabric to produce shrinkage in advance by increasing the density of the fabric, reduce or avoid the shrinkage of the fabric during use, and make the color of the fabric more bright and gorgeous.

Exclusive Agent in Bangladesh: Texlink Service and Trading (Click to contact us)

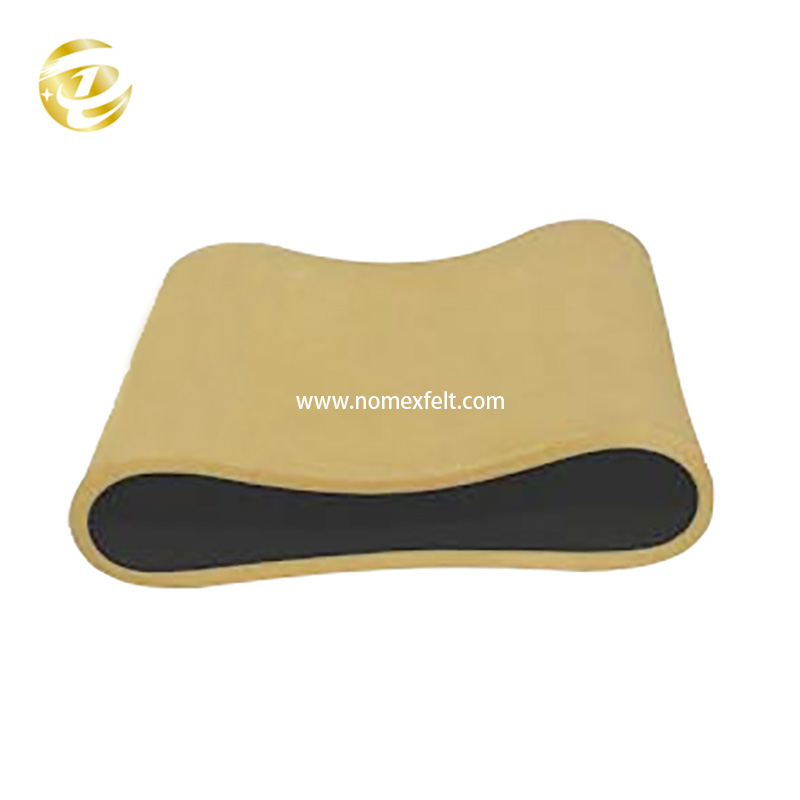

The sanforizing rubber belt produced by our company is made of imported high-quality raw and auxiliary materials, refined by advanced rubber formula and unique processing technology. Our sanforizing rubber belt effectively overcomes the disadvantages of traditional pre-shrunk rubber.

| Brand Name: | PURE | Type: | Other |

| Material: | 100% Natural rubber | Color: | Off-White |

| Heating roll temperature | <130℃ | Rubber blanket tension | 2.3% |

| Dimension(L*W*H): | Customized Size | Thickness: | 50mm-73mm(Customized) |

| Application: | Sanforizing machinery | Place of Origin: | Guangdong, China |

A Sanforizing Rubber Belt is a rubber belt used for shrinkage finishing machines, which can make fabrics or denim shrink in the compression unit. Sanforizing Rubber Belt has the following features:

Sanforizing Rubber Belt is the best choice for your shrinkage finishing machines. It can improve the quality and efficiency of your fabrics and denim production. Please contact us for more information and quotation.

Payment method

● The industrial sanforizing rubber belt manufactured by Foshan Pure Technology can use T/T, Paypal, Western, Union, L/C, and other payment methods.

? Click the button in the bottom right corner to contact us for more payment methods. ?

Heat Transfer Felt Detailed View

Application

●sanforizing rubber belts is mainly used for finishing and pre-shrinking fabrics in the printing and dyeing industry.

Click the Right chat window to contact us now

We actively promote the modern enterprise management system and were awarded ISO9001:2008 EWC quality system certificate etc.

We have QC staff to inspect every process and raw material to ensure the products in good quality. Advanced equipment like mechanical needling and carding machine etc.

|

Raw material preparation Select appropriate rubber and compounding agents, weigh accurately according to a certain formula, and process certain materials, such as cutting, crushing, screening, drying, etc. |

|

|

Masting The raw rubber is mechanically masticated on a masticating machine or thermally masticated on a thermal plasticizing machine to break the molecular chains of the raw rubber, reduce elasticity, and increase plasticity. |

|

|

Mixing Mix the plasticated raw rubber and compounding ingredients on an open or closed rubber mixer to make the compounding ingredients evenly dispersed in the raw rubber to form a mixed rubber. |

|

|

Calendering The mixed rubber is pressed into a film of a certain thickness and width through a calender, or a thin layer of glue is applied to the textile to form a glued fabric. |

|

|

Forming The film or rubberized fabric is formed through a mold or extruder to make a Sanforizing Rubber Belt in various shapes and sizes. |

|

|

Vulcanization Put the formed Sanforizing Rubber Belt into a vulcanization tank or vulcanization box, and vulcanize it at a certain temperature and time to form sulfur bridges between rubber molecules and transform it into an elastomer. |

|

Package And Transport

Our company’s Sanforizing Rubber Belt is packaged in wooden boxes in the textile industry. Wooden box packaging has the following advantages:

●Professional technical team to provide you with tailor-made services. According to the specifications and requirements of the Sanforizing Rubber Belt provided by customers, design and manufacture products that meet the requirements.

●Professional textile machinery solutions experience, textile factory construction guidance. Find the right shrinkage finishing equipment for your business. Increase production efficiency.

● Professional procurement Services Team, we often sell Sanforizing Rubber Belt and have met many friends in the textile industry, Cooperative customers can purchase textile machines,

such as calendar machines, fabric pleating machines, heat transfer printing machines, Sanforizing machines, Compacting machines, ribbon transfer printing machine, heat press machines. reduce trouble and get a preferential price.

A: The Sanforizing Rubber Belt is a rubber belt used for shrinkage finishing machines, which can make fabrics or denim shrink in the compression unit. Sanforizing Rubber Belt is also called zero-zero shrinkage rubber belt.

A: Sanforizing Rubber Belt has the following features:

●High-temperature resistance, able to maintain stable performance under the action of high-temperature steam.

●Wear resistance, able to withstand long-term friction and pressure, not easy to deform and break.

●Good elasticity, able to adapt to different thicknesses and textures of fabrics, provides uniform shrinkage rate.

●Smooth surface, will not cause damage or pollution to fabrics.

A: Sanforizing Rubber Belt is mainly used for shrinkage finishing machines, to pre-shrink and stabilize various cotton fabrics and blended fabrics. Sanforizing Rubber Belt is especially suitable for shrinking denim and heavy fabrics.

A: The installation and replacement of the Sanforizing Rubber Belt need to follow the following steps:

A: The maintenance and extension of the life of the Sanforizing Rubber Belt need to pay attention to the following points:

Tips: Calender machine, Sanforizing, Compacting.

We are to provide high-quality supplies and solutions to reduce marginal costs for the boss who has problems in purchasing machinery spare parts. Leading manufacturer of heat-resistant felt belts Nomex felt factory – Pure Technologies Ltd.

Welcome to our company website, thank you for your letter, we will give you a reply in the first time, would you please leave your information and contact way!