Aluminum is one of the important non-ferrous metals and industrial basic raw materials. It is a national strategic material with huge market demand.

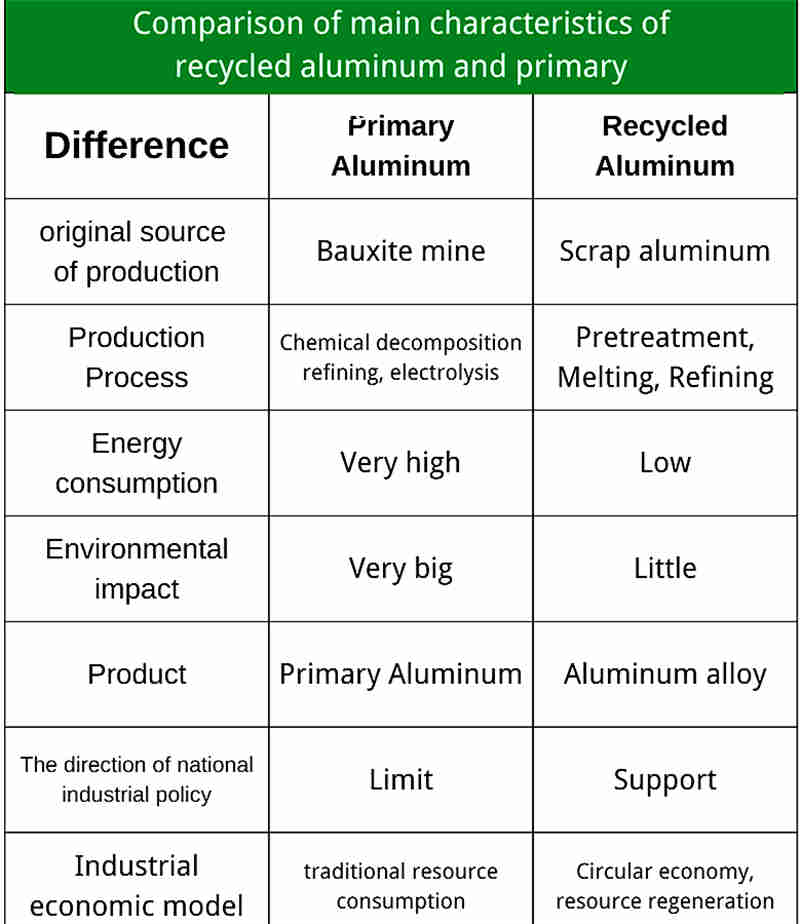

However, the production of primary aluminum consumes a lot of electricity, coal, and other resources, while producing obvious pollution and carbon dioxide emissions.

Therefore, it is listed as a restricted development industry by the state.

The production of recycled aluminum is fundamentally different from primary aluminum. Its main raw material is scrap aluminum, which can be continuously recycled.

It has the characteristics of saving resources, reducing the external dependence on aluminum ore resources, environmental protection, and economic advantages.

Compared with the production of primary aluminum, it greatly saves land, water, and electricity resources, and is an important part of the circular economy construction in the non-ferrous metal industry.

Under the “carbon neutrality” goal strategy, the development of the secondary aluminum industry is not only an important way to solve the problem of aluminum industry development resources, but also

It is also one of the main ways to achieve carbon emission reduction in the aluminum industry. The development of the secondary aluminum industry will be endowed with more responsibilities of the times.

Traditional primary aluminum production takes bauxite as raw material, and electrolyzed aluminum oxide to generate electrolytic aluminum (aluminum water). Electrolytic aluminum can be cast into aluminum ingots or added alloying elements to produce aluminum alloy products to achieve a certain performance.

It is widely used in aerospace, construction transportation, electronic communication and national defense, and other fields.

At present, aluminum alloy is the second-largest metal structural material after steel, and it is developing in the direction of high strength, high toughness, corrosion resistance, and material/structural integration.

Recycled aluminum mainly appears in the form of aluminum alloy, which is the aluminum alloy or aluminum metal obtained by remelting and refining waste aluminum and scrap aluminum alloy materials or aluminum-containing waste, which is an important source of metal aluminum.

Its production process saves the complicated mining process and avoids the production of a large amount of red mud in the primary aluminum production process.

In terms of energy consumption, the main fuel used in recycled aluminum is natural gas, etc., and there are almost no recycled aluminum enterprises that use electricity as smelting energy.

In terms of waste discharge, limited wastewater can be recycled after simple precipitation to achieve zero discharge.

Terminals are mainly used in automobiles, motorcycles, mechanical equipment, communication electronics, and household appliances and furniture industries.

The recycled aluminum industry not only has huge potential and advantages in terms of energy-saving,

And with the continuous improvement of secondary aluminum production and processing technology and the continuous improvement of management level, the increase in output,

The importance of the secondary aluminum industry will become more and more obvious, and it will have a larger and broader demand and utilization space, and will surely realize an important measure of carbon neutrality at an early date.

The secondary aluminum industry must adhere to green and low-carbon development, and run the concept of green, low-carbon, and circular development throughout the entire development process of the secondary aluminum industry;

Make full use of both domestic and international markets, adhere to dual-cycle development, expand the scope of imported raw materials, and promote overseas layout,

Further, strengthen and improve the domestic recycling system and raw material guarantee system to ensure the stable supply of raw materials; strengthen basic research, accelerate the realization of modernization, automation, intelligence, and grade-preserving utilization of technical equipment, improve the scientific and scientific level of sorting and processing, and improve the level of key technologies and intelligent level, strengthen the research and application of complete sets of equipment;

Further, build the standard system for the development of the secondary aluminum industry, promote the intensive and standardized development of the industry, promote the industrial park and large-scale development; Accelerate the process of international development, promote the development of the secondary aluminum industry, promote the sustainable development of the aluminum industry, and help achieve the goal of carbon neutrality as soon as possible.

Under the background of carbon neutrality goal, the development of the secondary aluminum industry has more theoretical and practical significance than any period, and it is also more necessary and feasible than any period.

In the new era, promoting the green, low-carbon, and circular development of the secondary aluminum industry will help to transform from a “big country in the aluminum industry” to a “powerful country in the aluminum industry”.

Contribute to the achievement of carbon neutrality goals in the non-ferrous metal industry.

The recycled aluminum industry is not a high-energy-consumption and high-pollution industry, but a circular economy industry.

It is an important part of ecological civilization construction, and an important way and key area for the realization of carbon neutrality.

The development of the secondary aluminum industry has a long way to go, with a glorious mission and a great responsibility!

Foshan Pure Technology Co., Ltd. is a leading manufacturer of heat-resistant industrial felts.

Among the products are a high-temperature roller, Heat resistant pad, Seamless belt.

It is an accessory that needs to be used in the machinery used in the aluminum industry. For transporting aluminum profiles.

To meet the temperature requirements, difficult to wear.

If you need information about the aluminum industry, you can contact us: [email protected]

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The extrusion machine is the leading equipment for the production of aluminum profiles. The quali...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

Nomex, an intermediate aramid, also known as aramid 1313. It is characterized by good heat resist...

In the 1960s, the Dupont developed a kind of aramid composite material, it is Kevlar. It has very...