In the hotel linen ironing industry, roller ironing machines are key equipment for ironing large items such as bed sheets and quilt covers.

However, in actual operation, sometimes a troubling problem occurs: after the linens are ironed, obvious vertical lines like “rutting marks” appear on the surface of the linens and quilt covers.

These vertical lines are regular or irregular strips, extending from one end of the linen to the other, which seriously affect the quality of linen ironing.

Therefore, effectively solving this problem of linen ironing is crucial to maintaining the normal operation and market competitiveness of the laundry plant.

If you don’t rinse your linens properly when washing them, detergent or softener residue may remain on the fabric. This residue can make the fabric feel sticky. Also, if you don’t spin dry them properly after washing, the fabric will still be damp when it goes into the ironing machine.

The sticky and wet fabric enters the hot ironing machine. During the ironing process, the fabric becomes even stickier under the high temperature and pressure. In the ironing machine, the rollers press the fabric and roll it. The sticky, wet fabric easily sticks to the rollers or sticks itself together.

When the machine moves, it will forcibly pull the stuck part apart. This pulling apart process will drag out vertical lines on the fabric.

In addition, fabric will become soft when it is too wet, and soft fabric will be more easily deformed. When the machine force is uneven, it is also easier to form such vertical lines.

Operators should rinse the sheets and quilts more and rinse them clean to remove the detergent and softener left on the fabric.

You can rinse them several times or for a longer time. Check the clarity of the rinse water to determine whether it meets the requirements. Some fabrics or detergents are special and may require more water or a few special additives to ensure that they are really clean.

Set the spin time of the washing machine to be longer. The longer the fabric is spun, the faster the machine turns, and more water can be spun out.

When the fabric has less water, it will not be too wet when it enters the ironing machine. The fabric is not so wet, and it is easier to iron it in the ironing machine. In this way, it is not easy to stick together or wrinkle.

At the same time, check whether the spin speed and centrifugal force of the washing machine meet the requirements to ensure that the equipment can achieve the best spin effect.

The condition of the internal components of the ironing machine directly affects the ironing effect of the linen. Common equipment problems include: The ironing belt used to transport the fabric in the ironing machine is not flat.

The isolation shaft in the ironing machine may be broken or not smooth. The guide belt used to guide the fabric is tied too tightly.

Uneven flatwork ironing belts or abnormal guide rollers cause uneven force and pulling of linens during conveyance; overly tight guide belts overly constrain linens. Some areas may be over-rubbed or squeezed, resulting in vertical lines.

If the surface of the isolation shaft is not smooth or abnormal, it will produce uneven resistance or friction when the linens pass through, causing the linens to be pulled at a certain point, forming strip marks.

The function of the guide belt is to guide the linens to enter the ironing area smoothly.

If it is tied too tightly, it will overly constrain the free extension of the linens, making it difficult for the linens to be fully flattened during ironing, and they will be forced to stretch to form vertical lines.

You should check the tape regularly to see if it is flat, wrinkled, or damaged. If you find that the tape is loose or wrinkled, you need to adjust it immediately. If the tape is severely worn or torn, please replace it in time to avoid surface problems of the tape damaging the fabric.

Check the roller

Confirm that the surface of the guide roller is smooth, without wear or deformation. Turn the guide roller by hand to confirm that it rotates freely and without jamming. If any problems are found, they should be repaired or replaced to ensure that the linens can pass smoothly and unhindered during the conveying process.

Adjust the tightness of the guide belt

According to the equipment manual or experience, the guide belt should be adjusted to a “moderate” state, which can effectively guide the linens without applying unnecessary tension to them.

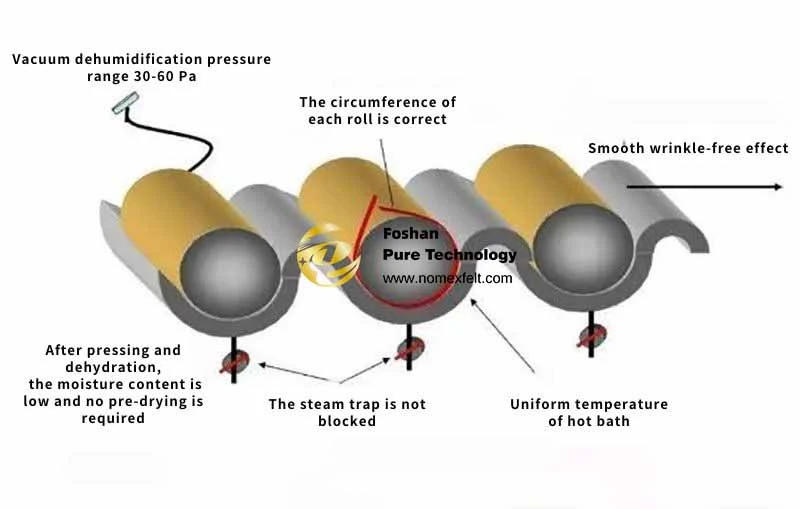

In a multi-roller ironing machine, there is a certain speed difference between the rollers, i.e., “sparseness”. This is to ensure that the linens can be ironed smoothly and fully.

If the speed difference between the front and rear rollers is not set properly, or the moisture content of the linens is too high when entering the ironing machine, vertical lines may be generated.

When the linen with high moisture content enters the front roller, if the pressure of the front roller is too large and the speed is too fast (large sparseness), the linen at the rear roller will be “pushed” out forcefully, forming vertical lines.

When the moisture content of the linen is high, it is more flexible and easier to deform.

If the pressure of the front roller is set too high at this time, or its running speed is too fast relative to the rear roller (that is, the sparseness is too large), the front roller will generate a huge “pushing force” forward when strongly squeezing and pulling the linen at high speed.

This force will drive the rear linen that has not yet fully entered the front roller, causing it to be pulled strongly instantly, thus forming vertical lines on the surface of the linen that are difficult to eliminate.

Adjust the speed difference

If your linen iron has only recently developed these vertical stripes, and everything was working fine when ironing linen before, then you should first check and adjust the “gap setting” between the rollers. Sometimes this setting can be changed accidentally.

We would recommend that you refer to the machine manual or your operating experience to understand the optimal gap corresponding to different fabrics (such as material, thickness, and moisture content).

Next, adjust the gap between the drums to the appropriate range. This is to ensure that the fabric can pass smoothly between the drums. We want to avoid excessive stretching of the fabric or accumulation between the drums.

Reduce the moisture content of the sheets

As mentioned above, high moisture content is the root cause of many linen ironing problems.

Therefore, when dealing with the problem of sparseness, it is also necessary to emphasize sufficient dehydration in the washing process to reduce the moisture content of the linens when they enter the ironing machine.

The lower the moisture content, the better the stability of the linens under high temperature and pressure, and the less likely they are to be pulled and produce vertical lines.

If the surface of the ironing roller is worn, the internal parts of the ironing machine will inevitably age and wear out after long-term use.

For example, the surface of the ironing belt may no longer be smooth, and may be dented or scratched; the stability of the pressure system may decrease, resulting in uneven pressure when ironing the linens.

These will directly affect the ironing effect of the linens, resulting in vertical lines or other defects.

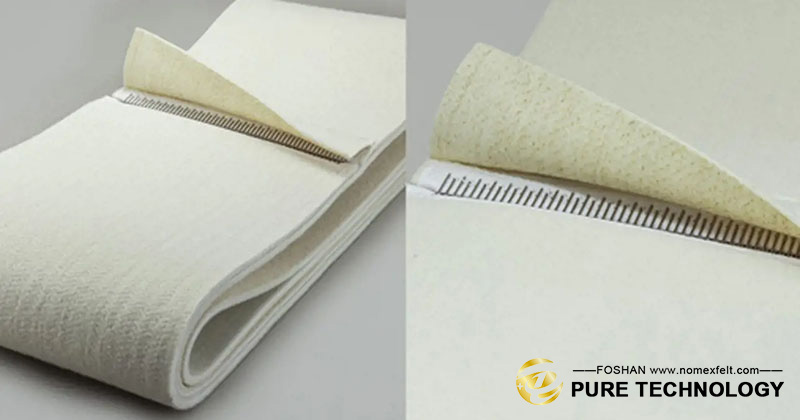

As a professional conveyor belt manufacturer, we are committed to providing you with high-quality ironing belt solutions to completely solve your ironing problems.

Smooth surface: Ensure that the sheets are evenly stressed during ironing, reducing friction and pulling.

High temperature and wear resistance: Ensure that they will not deform or age under long-term high temperature and high-pressure work, and maintain a stable ironing effect.

Good breathability (for some ironing tape types): Helps to discharge moisture, accelerates the drying of sheets, and reduces adhesion and wrinkles caused by moisture. Low friction coefficient: Reduce the resistance between the linen and the ironing belt, allowing it to pass more smoothly.

Choosing our professional Nomex ironer belts means choosing higher efficiency, lower rework rate, and better customer experience. Contact us now and let our professional team provide you with customized ironing tape solutions.

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The aluminum extrusion machine is the leading equipment for the production of aluminum profiles. ...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

What is Nomex? Meta-amide, or meta-phenylene isophthalamide, is made from meta-phenylenediamine a...

Kevlar fiber Introduction In the development of materials science, Kevlar fiber has particularly ...