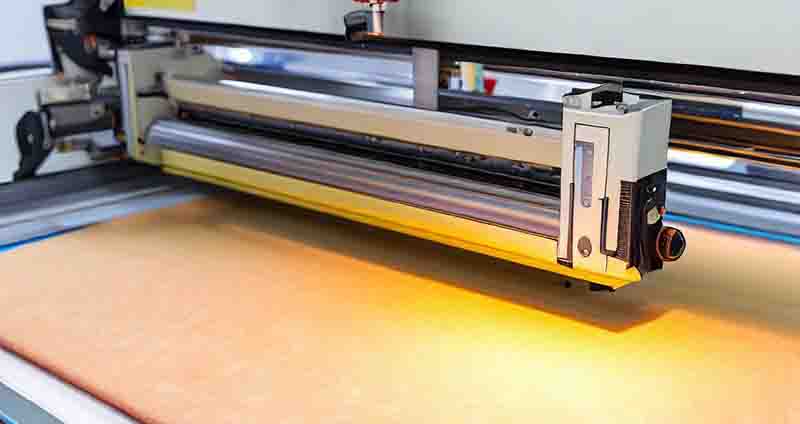

Heat Transfer Printing Felt Blanket is a special blanket.

It is used for heat transfer printing machines. It transfers the pattern from paper to fabric.

It also provides pressure and temperature for printing.

Heat Transfer Printing Felt Blanket is made of 100% aramid fiber (Nomex).

This fiber has many good features. For example, it can resist high temperatures, wear, corrosion, etc.

It can also ensure printing quality and efficiency.

But if we do not care for it well, it will have some problems. For example, it may deform, scorch, break, or damage.

This will affect the printing effect and safety. So we need to know some simple and valuable ways to care for it.

This will make it work better and last longer.

We need to clean Heat Transfer Printing Felt Blanket regularly.

We need to remove the dust and stains on it.

This is because, during printing, the blanket will touch many things. For example, paper, ink, fabric, etc.

These things will leave some residue on the blanket. This will make the blanket uneven or sticky.

This will affect the printing effect and blanket life. We can use a soft brush or vacuum cleaner to clean the blanket.

Or we can use a damp cloth or neutral detergent.

When cleaning, we need to be gentle and follow the direction of the blanket texture.

We need to avoid damaging the fiber structure of the blanket.

We must avoid Heat transfer felt in high temperatures for too long.

This may cause the blanket to change shape or burn.

This is because Heat transfer felt is made of high-temperature resistant fiber.

But if the temperature is too high (more than 240℃), it will make the blanket shrink or harden.

This will affect its elasticity and pressure transmission ability.

So when using Heat transfer felt, we need to adjust the right temperature according to different materials and processes.

And when we stop using it, we need to turn off the power or lower the temperature in time.

We must avoid letting the blanket stay at a high temperature for too long.

We need to store Heat transfer felt properly.

We should not fold or compress it.

This may damage the structure and elasticity of the blanket.

This is because Heat transfer felt has a seamless ring shape.

If it is folded or compressed, it will make the blanket have creases or deformations.

This will affect its flatness and uniformity.

So when we do not use Heat transfer felt, we need to put it in a dry, ventilated, and cool place.

And we need to keep its original ring shape. We should not stack it with other items.

We need to rotate Heat Transfer Printing Felt Blanket periodically.

This will make it evenly stressed and avoid local wear or looseness.

This is because during printing Heat Transfer Printing Felt Blanket will rub with the drum and fabric.

This will make the blanket wear or loosen in some parts. This will affect its thickness and density.

So we need to rotate the direction of the blanket every once in a while (usually 3-6 months).

This will make it receive the same pressure and temperature at different positions. This will extend its service life.

By using these ways, we can care for Heat Transfer Printing Felt Blankets well.

We can make it work better and last longer.

Of course, besides these ways we also need to choose a good supplier who can provide us with high-quality blankets and help us when we have problems Pure Technology Company Co., LTD is such a supplier they use pure Nomex material to make the best blankets they also have a professional team and good service attitude If you have any questions about Heat Transfer Printing Felt Blanket you can visit their website: https://www.nomexfelt.com/ You can also follow their Facebook: https://www.facebook.com/nomexfelt you can contact them anytime.

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The aluminum extrusion machine is the leading equipment for the production of aluminum profiles. ...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

What is Nomex? Meta-amide, or meta-phenylene isophthalamide, is made from meta-phenylenediamine a...

Kevlar fiber Introduction In the development of materials science, Kevlar fiber has particularly ...