Heat transfer printing, a mechanical term that may seem unrelated to our daily lives, has actually already quietly permeated every detail around us.

From the personalized T-shirts we wear every day to the mugs on our desks, and the currently popular phone cases and backpacks, almost all these customized products are closely related to the heat transfer printing process.

You may not have noticed, but these exquisite patterns and designs are precisely presented through heat transfer printing technology, perfectly showcasing creativity and individuality.

Heat transfer printing is a method of creating custom designs on fabrics. It involves transferring a design or artwork onto a substrate using heat and pressure. It is particularly suitable for producing small quantities of personalized and customized goods, as well as printing patterns containing full-color images or photographs.

Heat transfer vinyl printing

Heat transfer vinyl is a specialty vinyl material that can be cut into any design, shape, or size you wish to decorate anything. It has a slightly raised feel, is highly washable, and is suitable for most fabrics.

Heat transfer silk screen printing

The applicability of screen printing is very similar to that of heat transfer printing. Screen printing is a printing technology that coats ink onto the surface of an object and uses a screen and ink to transfer images onto T-shirts or other textiles. It is commonly used for printing on flat and curved surfaces.

Heat transfer sublimation printing

Sublimation is a printing technique that transfers images onto materials. It uses heat and pressure to imprint the image into the fibers of the material, creating a durable and highly accurate representation of the original design.

Sublimation transfer preserves the material’s original texture and provides a pleasant feel and appearance.

DTF Heat Transfer printing

Direct-to-film (DTF) printing is a heat transfer-based printing process that prints the design onto a PET transfer film, which is then adhered to the film using hot melt powder. After drying, the film is heat-pressed onto various fabrics.

Compared to traditional heat transfer printing or DTG direct-to-garment printing, DTF achieves excellent adhesion and softness on a variety of materials and has lower requirements for fabric materials.

First, check the condition of the heat press and set the temperature (approximately 325°F for cotton, approximately 300°F for polyester), pressure, and time according to the different materials. Second, select suitable fabric and transfer paper, ensuring that the material matches the printing method (such as HTV or sublimation).

Then, create the pattern using design software and print it to scale, cutting and removing any excess. Before transfer, accurately position the pattern, keep the fabric flat, and use a heat press printing felt, or a Teflon protective layer to fix it. During heat pressing, control the temperature, time, and pressure to ensure even heating.

Finally, depending on the transfer method, perform hot or cold peeling to check if the pattern is clear, the colors are vibrant, and the adhesion is firm.

First, cleaning the heat transfer felt of the equipment is a crucial step. For information on proper cleaning methods, please read this article. Wipe the felt with a white cloth to ensure there are no stains or residues. If the mat is too dirty, it is recommended to replace it with a new one to avoid affecting the heat transfer effect and the quality of the pattern.

Use a temperature gun to measure the temperature of the drum

Before production begins, the temperature of the roller heat transfer machine is adjusted according to the fabric type and pattern complexity required by the order.

An infrared thermometer is used to check the actual temperature of the rollers, ensuring it is within the preset operating range. According to industry standard test results, the standard heat transfer temperature range for polyester fabric is 210–230°C.

The temperature is adjusted as needed depending on the fabric type. This temperature range is derived from our more than ten years of experience in manufacturing heat transfer felt. Controlling the temperature within this range ensures optimal colorfastness and saturation.

Heat transfer time settings

The normal time of transfer is 35–45 seconds, depending on the type and thickness of the fabric. For precision in the time of transfer, it’s best to test with small pieces of cloth, starting the timer once it enters the roller and stopping when it exits the roller. Adjust the printing speed based on test results so that printing time will be the same for every batch.

Pressure settings and adjustments

The main factor that affects the heat transfer printing result is pressure. Different thicknesses and types of fabric need to be adjusted by appropriate pressure. Thin fabrics require light pressure, while thick or coarse fabrics need high pressure.

The adjustment of pressure should also consider the feel of the fabric (such as softness and density).

Temperature control for some heat-sensitive fabrics, like certain blends and polyester, should be between 190–210°C. The transfer time can be extended appropriately to 40–50 seconds to avoid possible damage to the fabric or pattern peeling caused by excessive heat.

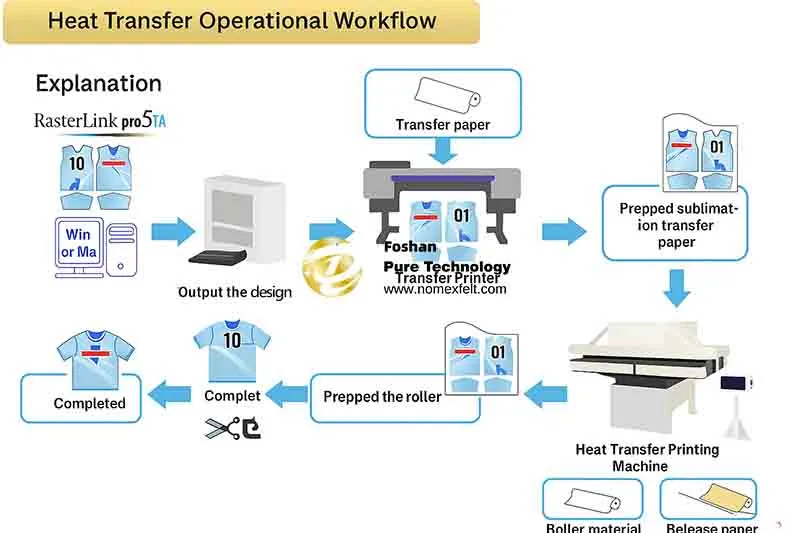

Place the transfer paper on the target material, aligning the pattern with the fabric. Heat and press the material through a heat transfer machine. The ink on the transfer paper transfers under the influence of heat to the surface of the target material.

Ensure that during the process of transfer, the fabric lies flat without wrinkles or foreign particles. After the transfer is complete, the fabric is gradually cooled through a cooling system to avoid the high temperatures from affecting the pattern.

After the operation is completed:

(1) Remove the transfer paper and the object to be transferred from the machine.

(2) Check the transfer effect to confirm that the pattern is clear and the color is bright.

(3) Take out the positioning bracket and pattern mold and clean them completely.

(4) Shut off the power and air supply, then clean the site.

The Heat Transfer Printing Machine is the core equipment in the heat transfer printing process. Depending on production needs, there are two common types of hot presses: flatbed heat press machines and roller-to-roller heat transfer machines.

Flatbed heat presses are suitable for small-batch, single-piece customization and offer high operational flexibility, while roller-to-roller heat transfer machines are suitable for large-scale, continuous production, capable of handling large-format materials and providing higher production efficiency.

Different types of heat transfer require different heat transfer papers or films. For sublimation transfer, specialized sublimation paper is needed, while for vinyl heat transfer, a specialized heat transfer film is used. The choice of each transfer paper and film depends on the type of material and the specific transfer requirements.

Besides the main equipment, such as the heat transfer machine and heat transfer paper, the heat transfer felt is a crucial component that cannot be ignored in the heat transfer process.

In our experience providing technical support to numerous apparel and advertising fabric manufacturers, we have found that keeping the surface of the heat transfer felt clean can improve the clarity of the pattern by approximately 15%.

The heat transfer felt, acting as an intermediary layer between the roller and the substrate, serves to evenly distribute pressure to every part of the transfer pattern and effectively ensure stable heat transfer. It is made of high-temperature-resistant Nomex fiber.

Advantages: High temperature and pressure resistance, buffers thermal shock, extends equipment and substrate lifespan, and improves the clarity and color saturation of transferred patterns.

Applications: Mass production printing, sportswear printing, advertising flag production, wide-width fabric transfer printing, industrial fabric printing, etc.

Heat transfer felt is subject to high temperatures, friction, and tension during use, requiring regular checks of its flatness, thickness, and wear condition, and timely replacement. Cleaning should be performed when the felt is cooled to avoid injury from hot handling. Using damaged or contaminated felt may result in poor pattern quality, peeling, or color spots.

Uneven temperature distribution can lead to inconsistent printing depth. Heat transfer printing requires precise temperature control; excessive temperature deviation can cause the pattern to become blurry. Uneven pressure distribution can result in unclear areas of printing, and the roller speed and temperature must also be matched.

Processing problems caused by pressure and heat transfer during transfer; issues with the material and process of the transfer film; and issues with the fabric being transferred.

Reasons for color fading and color difference in heat transfer printing

Fabrics have varying ink absorption capacities, resulting in different colorfastness levels. Insufficient transfer temperature or time can also compromise colorfastness. Ink quality also plays a role; using poor-quality ink can lead to color fading and short-lasting colors.

As a professional high-temperature felt manufacturer, we have long provided high-performance felt products for global customers to use in roller heat transfer machines, flatbed heat presses, and sublimation printing machines.

Our products have been successfully applied in textile printing production lines in Turkey, India, Vietnam, Mexico, and other countries, receiving unanimous praise from local customers. Choosing the right heat transfer felt is not only key to improving quality, but also an important guarantee for enterprises to achieve efficient production and reduce costs.

If you are looking for reliable, durable, and customized heat transfer felt products, please contact us. Our products are ISO 9001 quality management system certified and have been adopted and validated by many international heat transfer equipment manufacturers (such as Monti Antonio and Klieverik). We will provide a one-stop solution based on your equipment model, transfer temperature, and production line requirements.

This article was written and verified by a technical team with 10 years of experience in textile machinery processes.

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The aluminum extrusion machine is the leading equipment for the production of aluminum profiles. ...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

What is Nomex? Meta-amide, or meta-phenylene isophthalamide, is made from meta-phenylenediamine a...

Kevlar fiber Introduction In the development of materials science, Kevlar fiber has particularly ...