By analyzing the characteristics of the GYC6SS aluminum profile used for large mechanical beams

The paper introduces the measures to solve the difficulties in designing the mold.

With the acceleration of urbanization and industrialization, economic development is increasingly restricted by the environment and resources.

Aluminum profiles are widely used in various fields of national economy because of their advantages such as lightweight and corrosion resistance.

At the same time, the profile section is developing in the direction of considerable size and abnormity

And the requirements of dimension accuracy and shape dimension accuracy are becoming higher and higher.

The design optimization of die 3GYC655 is one of the critical factors in the extrusion process of large section and multi-cavity complex aluminum alloy profiles.

Reasonable mold structure is not only an essential guarantee of forming and dimensional accuracy of profile products but Also an important guarantee of mechanical properties, internal organization, and surface quality of products.

This paper takes the GYC655 aluminum mold design of automatic beam as an example

To talk about a personal point of view for peer reference.

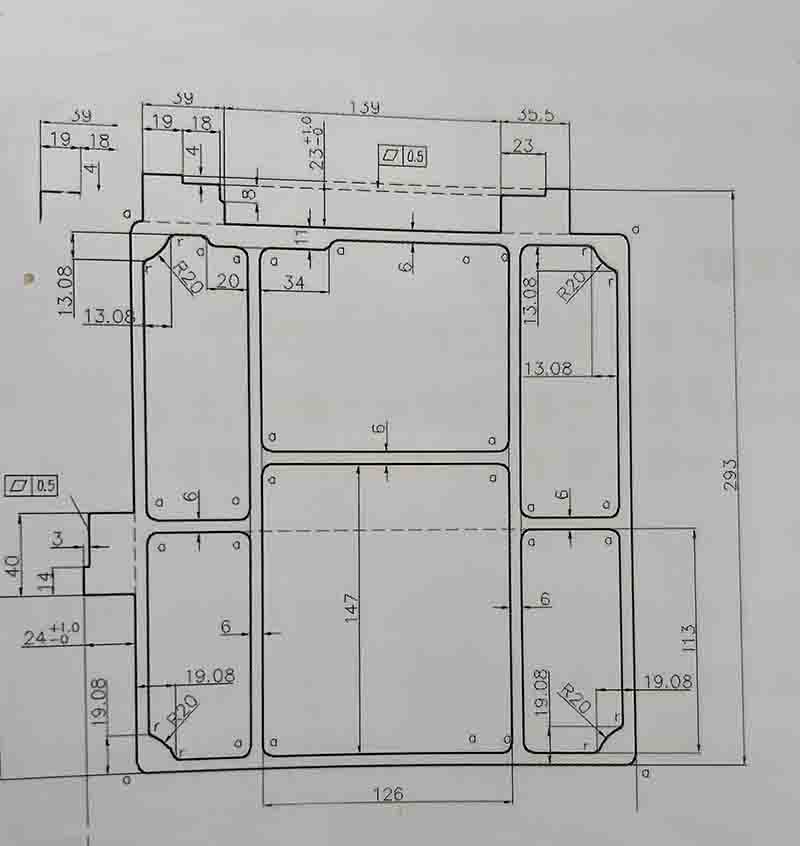

Figure 1

Figure 1 shows the section diagram and size requirements of the GYC655 profile. The main characteristics of the profile structure are:

1: The male head outer circle is large, the diameter reaches 380, widespread more need to expand the bar, increasing the design difficulty;

2: the size of the inner cavity is many and strict, and the flatness and twist degree has specific requirements;

3 Alloy grade 6005-T6, liquidity is not as good as 6063, high requirements for water supply.

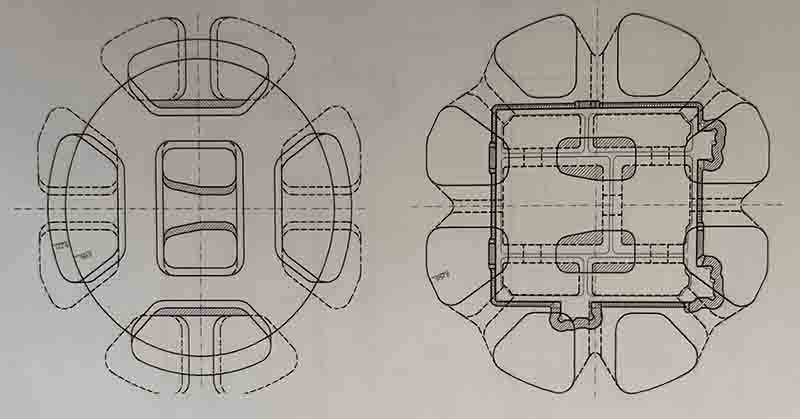

Figure 2

Specific design drawings: the weight of the profile is 38kg/m.

We choose an extrusion rod diameter of 406mm(7000T machine) machine to produce

Through calculation, the extrusion ratio coefficient is only:9.0, due to the structural characteristics of the profile

According to the machine size of 406mm rod diameter, the design of more shunt holes, the mold pressure is larger

It is difficult to adjust the size and proportion of the shunt hole;

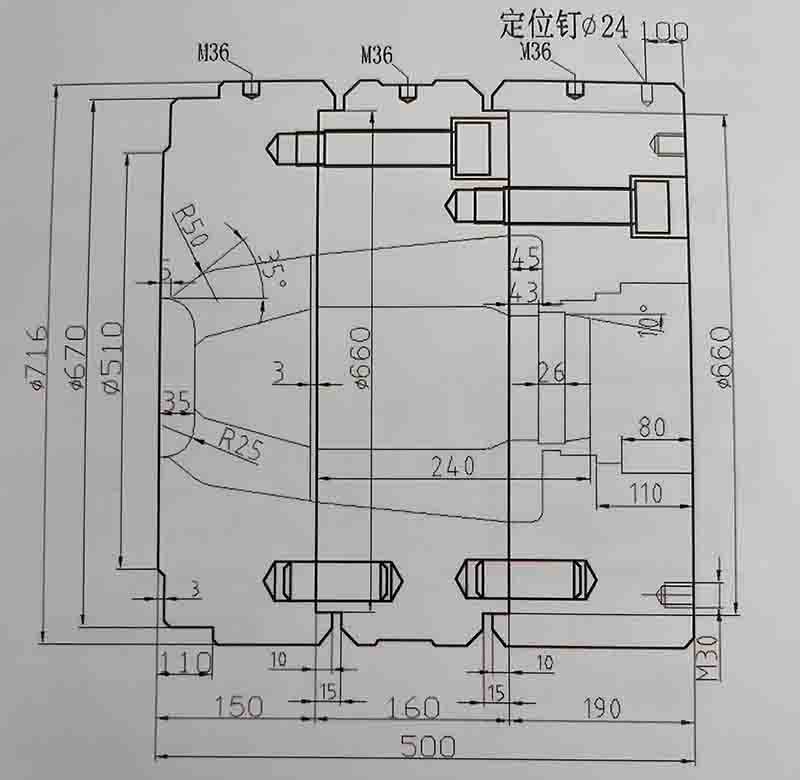

The outer circle is too large, so we choose the three-piece model which is more extensive and convenient for mold processing and manufacturing. Figure 3.

Since the mold is large and the extrusion ratio is not high, under the premise of ensuring the strength of the mold

To reduce the pressure in the extrusion process, the thickness of the thin guide plate is fixed at 150mm

And the material is milling and sinking at 35.

Figure 1 is the section diagram and size requirements of the GYC655 profile as shown in Figure 1.

The profile structure of four into eight out of the shunt hole design is the water for four large shunt holes

Discharge direction for eight small shunt holes uniform shunt.

This serves the purpose of evenly dividing the material and further reduces the pressure of the extrusion process (see Figure 3).

The thickness of the upper die is based on the shear stress and the flexural strength is less than 900MPa.

We recommend a thickness of 160mm. The meter weight of the profile is heavier.

And the depth of the closing chamber is set at 45m.

1: Pressure relief Angle is made in all the figures, and the thickness of the upper die is reduced to reduce pressure and speed up.

2: Figure 2: The main bridge of the diversion plate is 90, and the bridge width of the second bridge is only 50

Which reduces the resistance of the bridge position.

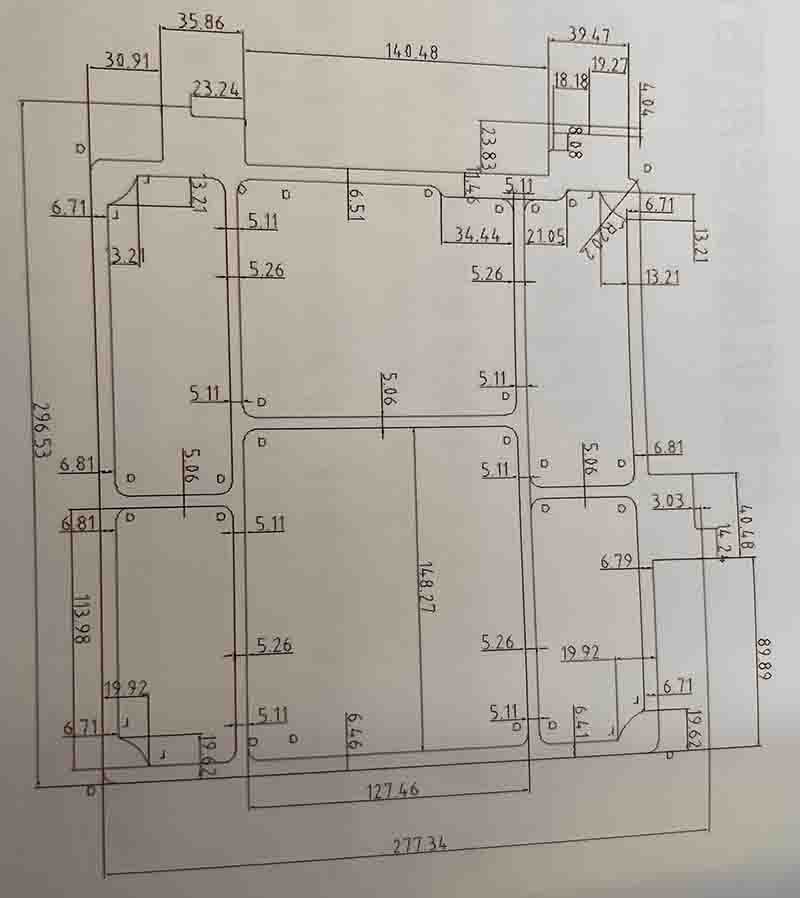

3: In the extrusion process, the mold will produce elastic deformation under extrusion pressure.

The elastic deformation of the mold will lead to the extrusion of the profile “wall phenomenon”.

product size is unstable, therefore, in the calculation of the size of the hole should be added to the “pre-deformation”. According to its location, the middle part of the reinforcement of the wall thickness is reduced

The wall thickness of the left and right ends of the appropriate thickening, The mold size of the profile are shown in Figure 4.

Figure 3

Figure 4

The characteristics of the extensive mechanical beam aluminum alloy profile die provided in this paper are that the shape is extensive.

The expansion is more, and the shear force and bending strength of the die are very large.

The design or processing is improper, and the die is very easy to crack.

Designers need to consider various factors, such as the impact of the elastic change of the mold on the wall thickness of the profile.

And then the impact of the elastic change on the life of the mold and the use of stability.

Peripheral shunt hole and back hole all flow balance, three-piece set how to reduce the pressure…….

This kind of profile references the above mold design case, and the processing of high-quality extrusion mold

in the delivery to customers to use, such as satisfactory answers.

To bring a good image and economic benefits to the enterprise

[1] Liu Jing ‘an Aluminum Alloy Extrusion Mold Manual 2012

[2] Li Minghuan large-scale industrial aluminum profile mold design and manufacturing

Article source: Aluminum profile Special issue

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The extrusion machine is the leading equipment for the production of aluminum profiles. The quali...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

Nomex, an intermediate aramid, also known as aramid 1313. It is characterized by good heat resist...

In the 1960s, the Dupont developed a kind of aramid composite material, it is Kevlar. It has very...