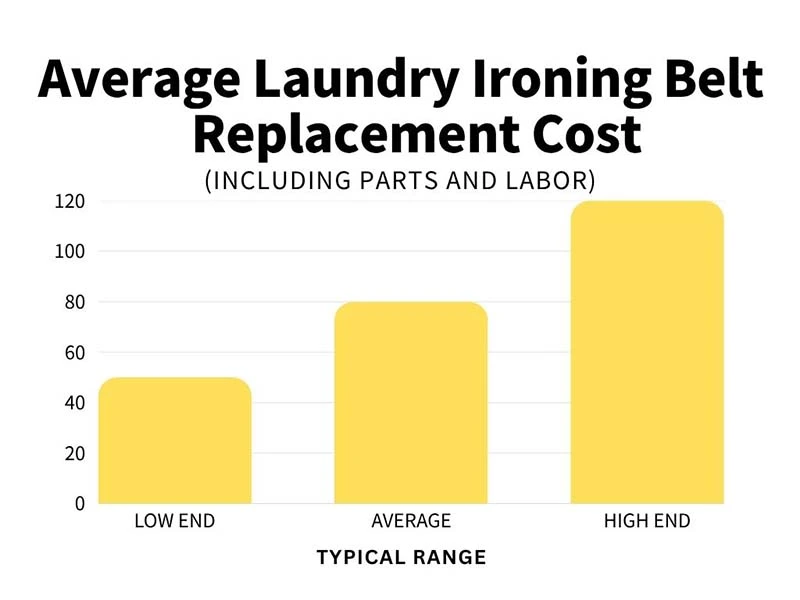

The average price of replacing a Laundry Ironing Belt for an ironing machine is between $50 and $120. This price includes the cost of the new part and the labor of the repair worker.

The specific total price will be affected by several factors. The type of belt, where to buy it, and the local labor charges. The ironing machine belt is a core part of the equipment.

The degree of wear and tear of the belt will directly affect the flatness of the clothes ironed and the service life of the machine itself.

When the Laundry Ironing Belt is broken or old, it must be replaced in time to ensure the normal operation of the equipment.

Average folding belt replacement cost – Chart

Labor costs make up a large portion of the cost of replacing a dryer belt. Most appliance repair technicians charge $20 to $30 for labor alone. The cost of the ironer belt portion can range from $30 to $90.

|

Cost to replace a Laundry Ironing Belt |

|

|

Factor |

Average cost |

|

Belt & lubricant |

$30 – $90 |

|

Labor |

|

|

Total cost |

$50 – $120 |

Ironing machine brand:

Higher end brands (e.g. Chicago, Jensen) and certain ironing machine brands (e.g. less common models) require more expensive parts or specialized labor, increasing the total cost.

The service life of the ironing machine:

The belt of a new machine (1-3 years) is less aged, and it may only need to be replaced (the cost is concentrated on accessories + labor). The original accessories are in sufficient supply and do not need to be customized. If it is an old model (more than 5 years old), the Laundry Ironing Belt may need to be customized, which will greatly increase the cost.

The risk of disassembly is high: long-term use will cause screws to rust and parts to age, which may easily damage other parts (such as gear wear), triggering additional repair costs.

Belt type: Different ironing machines use different types of ironing belts, and the prices vary. Universal belts have strong compatibility but poor durability.

Heat Resistance Laundry Ironing belts are more suitable for ironing machines and have a longer lifespan than other belts.

Labor and service fees: The repairman’s fee is related to three factors. The first is the repairman’s technical level. People with more experience charge more. The second is the difficulty of repair.

The more complex the machine structure, the more expensive it is. The third is the wage standards in different regions. For example, large cities charge higher fees than small cities. If other problems are found when the ironing machine is replaced, the overall repair cost will increase.

For example, the machine needs to replace bearings or repair the motor, which will cost extra. Maintenance items such as cleaning the machine or replacing parts will also increase the total cost.

It is best to have the technician check all problems before repairing to avoid hidden charges.

Commercial laundry ironing belts stretch during use. When the laundry belt tension can no longer be adjusted, the entire set of flatwork ironer belts must be replaced. Damaged belts should be replaced immediately.

To avoid excessive stress on the new, slightly shorter belt, it is necessary to replace the entire set of ironing belts. Look out for the following common indicators that your ironing belts need to be replaced:

⚠️ Symptoms: The motor makes a high-speed running sound, but the drum does not rotate.

⚠️Symptoms: The clothes are still not flat after repeated ironing in the same place.

⚠️ Symptoms: Some areas are overheated (burned) or the temperature is insufficient.

⚠️ Symptoms: A pungent smell similar to burning plastic is smelled.

⚠️ Symptoms: There are horizontal/vertical cracks on the surface of the belt, or it is partially disconnected.

⚠️ Symptoms: The sides of the belt become thinner, rough, or delaminated.

Garment factories and laundry factories use belts frequently, and 60% of the machines need to replace belts 2-3 times every year. High-quality high-temperature resistant belts can be used longer, generally 1 to 2 years, It depends on your usage.

First, look at the appearance: a good belt should have a smooth surface, without bulges or cracks.

Second, look at the material: directly read the instructions on the package, or ask the seller what material the belt is made of.

Third, test installation: If it is convenient, install the flatwork ironer belts on the machine and try it. After turning on the machine, listen to see if there is any noise and whether it rotates smoothly.

You can change the Laundry Ironing Belt of your ironing machine yourself. But it is better to have a professional do it. They have professional tools and skills. There are two advantages to changing the belt this way: first, it will not damage the machine, and second, it will be fixed quickly.

When changing it yourself, remember: never plug in the machine, as this is dangerous.

To extend the life of the Nomex Ironer Belt, here are some maintenance tips.

Wipe the belt and belt groove with a dry cloth every week to remove dust. If it is stained with oil, wipe it clean with a small amount of alcohol.

Check the tension of the belt every month. If it is too loose or too tight, adjust it with a tool. Do not iron more clothes than the machine specifies at one time. Too many clothes will damage the conveyor belt.

The machine should be placed in a cool and dry place. Humidity will cause parts to rust. Pay attention to two points when using it: first, do not bend the belt, and second, do not let heavy objects press on it. Doing so will prevent the belt from deforming.

Traditional belts break and age easily, and frequent replacement is costly and affects work efficiency. Our company’s ironing machine belt is the “savior” of your equipment!

As a leading felt belt manufacturer, we use high-quality, high-temperature resistant materials, and the belt surface is smooth and flawless, ensuring durability from the source.

Professional testing shows its service life is 2-4 times longer than ordinary belts. It can be adapted to a variety of mainstream ironing machine brands on the market, whether it is a new machine or an old model, it can be perfectly matched.

If you are interested in our products, please feel free to contact us

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The aluminum extrusion machine is the leading equipment for the production of aluminum profiles. ...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

What is Nomex? Meta-amide, or meta-phenylene isophthalamide, is made from meta-phenylenediamine a...

Kevlar fiber Introduction In the development of materials science, Kevlar fiber has particularly ...