Accurate measurement is the core of processing. Incorrect size will lead to the failure of finished products and the waste of resources. We need to use a steel ruler to measure.

Generally speaking, the size difference should not exceed 5mm, depending on the actual situation. After the measurement, it is necessary to design the pattern and the door-opening method, both of which are very important. Design the door opening direction (inward, outward, or horizontal) and the pattern to ensure coordination with the overall house design.

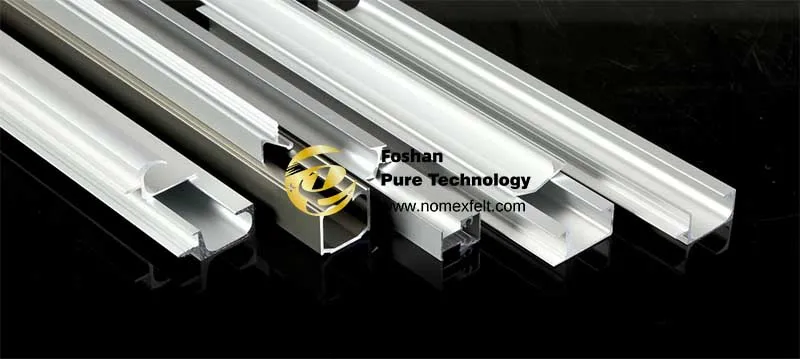

According to the calculated proportion of the required aluminum profile, various raw materials are reasonably allocated.

The aluminum ingot is heated to a specific temperature for melting, and a certain amount of alloy elements (typically magnesium and silicon) is added to the molten aluminum liquid.

The slag, waste gas, etc. in the melt are removed by corresponding refining methods.

Under qualified casting process conditions, the smelted aluminum liquid is poured into the casting machine cooled, and cast into round cast bars with expected diameters and specifications.

This step is simply to heat the aluminum rod to about 480-520℃, heat the aluminum rod to soften it, and then use an aluminum extrusion press to extrude various specifications of profiles.

Lay the aluminum rods flat on the rack to avoid placing them too close or stacked, and reserve safe operating space to prevent the aluminum rods from rolling or even falling.

Heat the aluminum rods and molds in the aluminum melting furnace to raise the temperature to 500℃, place the mold in the die base of the extruder, and put the aluminum rods into the extruder inlet for extrusion.

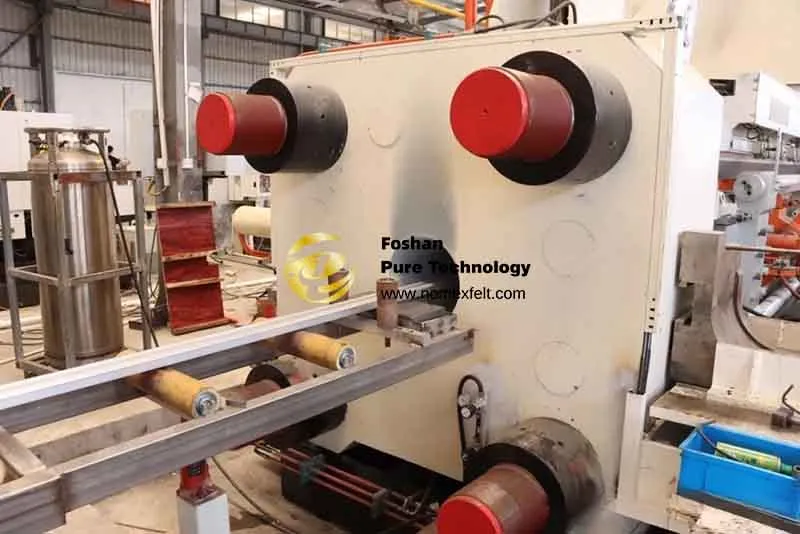

The extruded profiles come out of the discharge hole, and the head of the material is pulled by the double puller and preliminarily cut according to the set length.

The aluminum profiles formed by traction extrusion usually do not meet the straightness standard, which affects the subsequent use or operation of mechanical equipment.

The extruded aluminum profiles are sent to the Profile correction machines for straightening and then transported to the finished product area for cutting to size.

The aluminum profiles are still relatively soft when they are just produced.

In order to maintain the hardness of the aluminum profiles, and enhance their hardness, toughness, and service life, they are quenched in an aging oven and subjected to aging and heat preservation treatment at a constant temperature of 200°C for up to 150 minutes.

After the aging is completed, they can be taken out of the furnace and enter the cooling stage. They can be cooled naturally or artificially with a cold air blower.

At this time, the extrusion work is completed, and the extrusion of aluminum profiles with qualified appearance quality shape, and size is completed.

Surface fluorocarbon treatment sprays difluoroethylene on the aluminum alloy and its surface through electrostatic action, which has uniform color, and excellent anti-fading and anti-fouling capabilities.

The extruded aluminum alloy is put on the shelf, and the material is repeatedly cleaned according to the regulations in the pre-treatment area to thoroughly clean the surface oil stains.

Then it is chromized in the chromization tank, and a fine and stable chromized film will be formed on the surface. The good adsorption capacity can improve the adhesion of the paint, and finally, the chromized aluminum is placed in the drying furnace.

Before the aluminum is transported to the spraying production line, it is partially polished to ensure that the material is flat and dust-free. During the whole process, the aluminum is sprayed with powder at 200 degrees up and down by a spray gun to maintain the uniformity of the powder on the profile surface.

During the anodizing process, the aluminum alloy will form an aluminum oxide film on the surface through electrolysis. The oxidized aluminum alloy can be produced in a variety of colors through electrolytic coloring.

On the basis of oxidation, a layer of water-soluble acrylic paint film is covered on the oxide film through electrophoresis. The profile will have stronger water resistance, wear resistance, and abrasion resistance, and the surface will be smoother and more beautiful.

When producing aluminum windows, all purchased raw materials must be strictly inspected and controlled before entering the warehouse, and they must have a product quality guarantee.

The wall thickness, oxide film or coating composite film thickness, hardness, etc. of the aluminum profile should meet the requirements of the designed and produced aluminum window products.

There are also hardware accessories, auxiliary materials, cutting, and mechanical processing quality control. Quality control of the assembly process has a great impact on the quality of aluminum doors and windows.

It is a key process for quality control departments and quality inspectors to supervise and inspect. The quality control of the aluminum window packaging process is mainly to clean oil stains, surface attachments, and dust.

In addition to what I said above, there are some unknown details, such as the high-temperature felt of the processing machinery.

Many people think that such an inconspicuous spare part can determine the quality of aluminum windows.

In the aluminum extrusion production line, the PBO roller sleeve

is mainly used for the exhaust port and sliding table of the aluminum profile extruder.

When the aluminum profile is extruded through the die, its temperature is as high as 550°C, and ordinary materials cannot withstand such high temperatures for a long time.

But PBO fiber is a high-temperature resistant material with a maximum temperature resistance of 600°C.

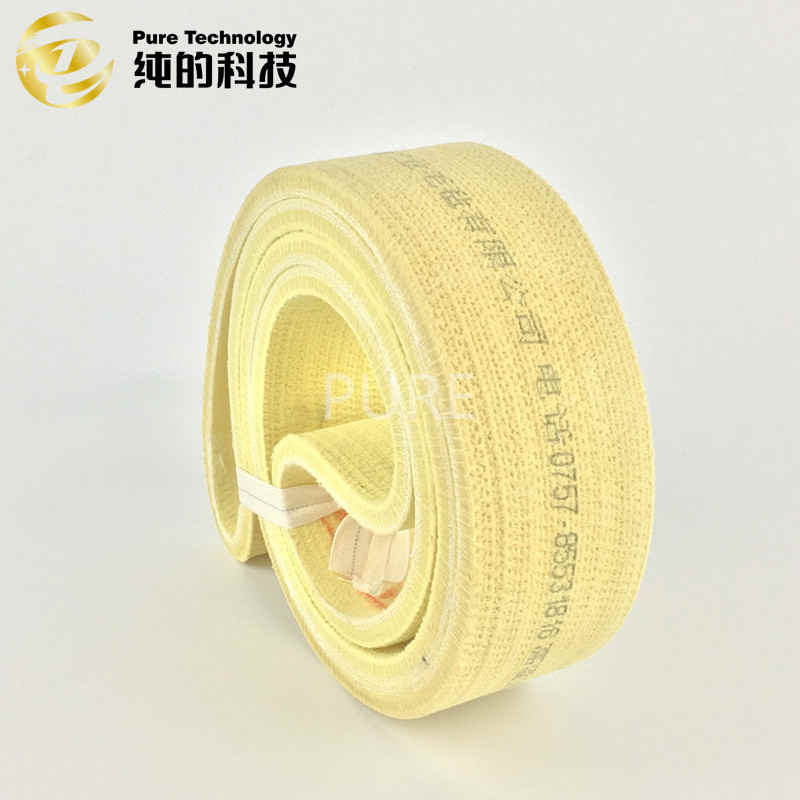

The Kevlar conveyor belt is a key component of the first and second operating tables of the extrusion production line. Its selection depends on the size of the extruder and the customer’s site conditions.

The conveyor belt has excellent characteristics such as high density, high-temperature resistance, and wear resistance. The cutting surface is smooth, without delamination and burrs, and aluminum profile pollution is eliminated.

Its core value lies in: combined with PbO roller, this high-temperature resistant felt belt can more effectively protect the surface quality of aluminum profiles.

Therefore, the quality of the felt belt (purity, heat resistance temperature, wear resistance) directly affects the quality of the final aluminum profile.

As a professional supplier, we provide high-quality felt tapes with higher purity, no impurities, excellent heat resistance, and wear resistance. Their effective service life is significantly better than similar products, and they are supplemented by perfect service guarantees.

If you want to improve the quality of your aluminum windows from the source, please contact: www.nomexfelt.com.

Aluminum windows are made of aluminum, light in weight, and high in strength, with a density of about 1/3 of that of steel. Aluminum windows have good sealing performance. Sealing performance mainly affects the use function and energy consumption of doors and windows.

Sealing performance mainly includes air tightness, water tightness, heat insulation, and sound insulation. Aluminum alloy doors and windows have good air tightness, water tightness, and sound insulation.

Aluminum alloy windows have good durability and are easy to use and maintain. It does not rust, fade, or fall off, requires almost no maintenance, and has a long service life for spare parts.

In addition, aluminum alloy windows have good decorative effects. There is an artificial oxide film on the surface and it is colored to form a composite film layer.

Which is not only corrosion-resistant and wear-resistant, but also has a certain fire resistance, and has a high gloss, which is generous and beautiful.

The manufacturing of aluminum alloy windows is a complex process that combines precise measurement, scientific proportions, strict technology, and meticulous quality control.

It is these careful designs and rigorous manufacturing that make aluminum alloy doors and windows a high-performance aluminum alloy window choice widely used in modern buildings.

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The aluminum extrusion machine is the leading equipment for the production of aluminum profiles. ...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

What is Nomex? Meta-amide, or meta-phenylene isophthalamide, is made from meta-phenylenediamine a...

Kevlar fiber Introduction In the development of materials science, Kevlar fiber has particularly ...