In the development of materials science, Kevlar fiber has particularly outstanding performance and is very eye-catching. Since its emergence, people have a new understanding of the strength and function of materials.

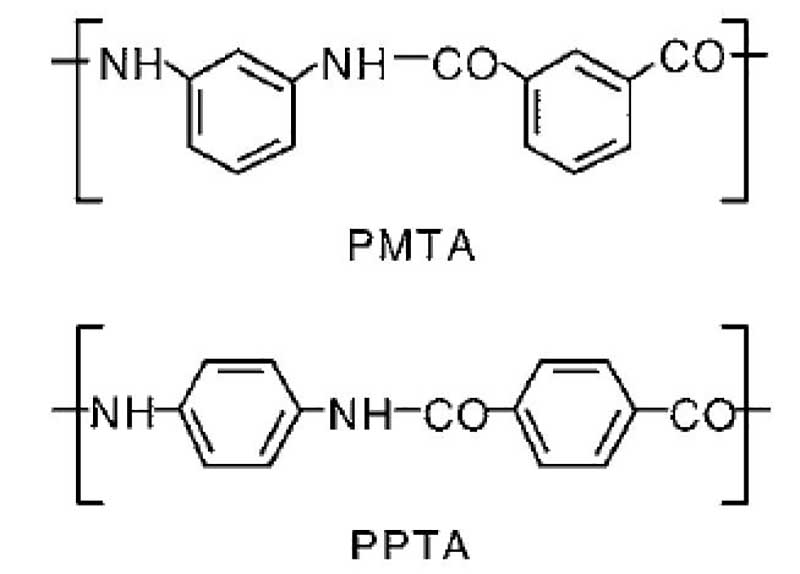

Aramid fiber has a short history and has developed rapidly. Industrialized aramid fiber was launched by Rhone-Poulenc in 1969 under the trade name Kermel, which is a meta-aromatic fiber.

The first industrialized para-aramid fiber was Kevlar fiber (Chinese translation: Kevlar fiber, which is PPTA fiber) launched by Dupont in 1972, and it occupied most of the para-aramid fiber market for many years. It was not until 1986 that the emergence of Twaron fiber from AkzoNobel of the Netherlands, Technora fiber from Teijin of Japan, and Aroms fiber from Russia broke the market monopoly system of Kevlar fiber.

The chemical name of Kevlar fiber is poly(p-phenylene terephthalate) (PPTA), and its molecular chain is formed by terephthaloyl chloride and p-phenylenediamine through polycondensation. In the molecular structure, benzene rings and amide groups are arranged alternately to form highly regular linear macromolecules.

This rigid molecular chain structure gives Kevlar fiber extremely strong intramolecular forces and excellent orientation. The molecular chains interact through hydrogen bonds, further enhancing the stability and strength of the material.

It has very good thermal stability, fire resistance, chemical resistance, insulation, and high strength and modulus. Comparing the physical properties of Kevlar with other fibers, it can be found that Kevlar is 2 to 11 times stronger than asbestos.

Is 1.6 times the strength of high-strength graphite, 3 times stronger than glass fiber, and 5 times the strength of steel fibers for the same weight. Kevlar has a very low density, almost half the density of asbestos.

fiber

Thermal stability: Kevlar brand fiber in the thermal test is very stable, until 600℃ without significant weight loss;

Low erodibility: showing lower erodibility than a half-metal sheet.

Kevlar is widely used in aerospace, shipbuilding, and friction materials because of its advantages.

kevlar fiber

Kevlar has density, high strength, good toughness, high-temperature resistance, easy processing, and molding, so people pay attention to it, and has been widely used in people’s daily lives. Because the material of kevlar is tough and wear-resisting, rigid and soft match aids, have the special ability that knife grabs not to enter. It’s called “armored guard” in the military. Kevlar laminates can be cut in half in weight for the same protection as fiberglass, and are three times as tough as steel to withstand repeated impact.

Kevlar properties:

1. Temperature resistance up to 500℃

2. Antistatic property

3. Permanent resistance to acid-base and organic solvents erosion

4. High strength, high wear resistance, high tear resistance.

5. No molten droplets are generated in case of fire, and no toxic gas is produced.

6. The fire cloth surface thickening, enhances the sealing, not broken.

Click to view the Kevlar belt.

1. Protective Armor: It can be used to make personal armor such as bulletproof vests, combat helmets, bulletproof masks, bulletproof vests, etc. Kevlar fiber is difficult to break and is laid in multiple layers. In this way, it can easily slow down the movement of bullets and shrapnel shells.

Due to the high strength of this material, it is made into body armor, bulletproof vests and other forms of protection for use by the military and other law enforcement agencies or journalists in war zones.

2. Protective clothing: Kevlar’s ability to withstand high temperatures and certain chemicals makes it a very common material in bulletproof vests and personal protective equipment. Kevlar can also be used in cut-resistant gloves, thermal insulation, flame-retardant blankets or helmets.

3. Motorsports: Kevlar is used in the manufacture of Formula 1 racing cars. In the automotive industry, it is also used in the manufacture of driver helmets, engines and vehicle fuel tanks, and is also widely used to reinforce motorcycle suits. The abrasion resistance of Kevlar fabrics makes it an excellent material for combating elbow or knee injuries.

4. Aerospace Industry: High toughness and light weight are key properties of the aerospace industry. That is why Kevlar is widely used in safe but lightweight space suits. Kevlar is also used as part of the landing system of spacecraft. Kevlar composite technology used on wings can even protect the jet engines of aircraft.

5. Aluminum industry: As the aluminum profiles are pulled from the extruder, independently acting fly-cut saws cut them to the appropriate lengths. The profiles are then transported along a Kevlar endless belt conveyor table to a stretching machine where they are cut to length on a precision finishing saw.

Finally, with the continuous improvement of high-performance raw materials and their preparation methods, the application of aramid fibers in new material functionalization fields such as electricity, magnetism, and energy has become possible, providing ideas for the multifunctional application of aramid fibers.

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The aluminum extrusion machine is the leading equipment for the production of aluminum profiles. ...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

What is Nomex? Meta-amide, or meta-phenylene isophthalamide, is made from meta-phenylenediamine a...

Kevlar fiber Introduction In the development of materials science, Kevlar fiber has particularly ...