Most linen service workers are familiar with the four elements of washing: chemical action, mechanical action, time, and temperature. These elements collectively affect the quality of washing.

Just as washing has its elements, ironing also has its elements.

According to LeBron’s US sales manager, LeBron, the key elements of ironing include: dehumidification – removing moisture from the linens as they pass through the ironing machine (tank ironing) or evaporating it (roller ironing); time – the speed and time required for ironing; pressure – the pressure required varies depending on the type of ironing machine (tank or roller ironing);

And temperature – the ironing temperature varies depending on the fabric type. All four elements directly impact the performance of the ironing machine and the quality of the linens produced.

Therefore, basic procedures and regular maintenance influence ironing performance and quality.

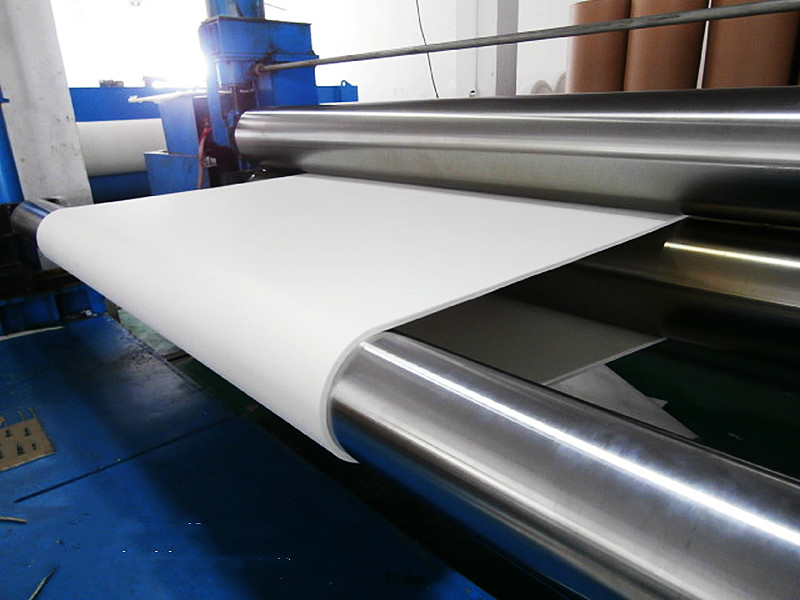

There are two types of ironing machines in laundry factories: roller ironing (heated by rollers) and trough ironing (heated by an ironing trough). Leber believes that roller ironing is generally used in laundry factories with smaller production volumes and is not suitable for large-scale, high-speed production.

One of the biggest differences between roller ironing and trough ironing is that roller ironing does not have an ironing trough.

She says, “After the linens enter the ironing machine, a series of guide belts and pulleys press the linens firmly against the rollers, guiding the linens forward and applying some pressure.”

There are generally two types of ironing machines: one heated by thermal oil and the other by steam.

Unlike traditional ironing machines, which use guide belts and pulleys to pull linens forward for drying and applying pressure, ironing machines place the linens between the hot metal ironing bed and rollers. She explained, “The concept of ironing is similar to ironing at home.

When ironing at home, there’s an ironing board underneath with a lining cloth, and the iron you hold is like the ironing board. As you apply pressure, the lining cloth absorbs moisture and simultaneously removes wrinkles.”

In a roller iron, temperature is distributed through the rollers themselves. In contrast, the heat source for an ironing machine comes from the ironing bed below. If powered by natural gas, the ironing machine is an integrated unit (no boiler is needed; heating is done independently). If steam heating is used, the steam is provided by a boiler.

Of all the equipment in a laundry, the steam-heated ironing machine is the most steam-consuming. Maintaining the correct steam pressure is crucial for the laundry to achieve the ideal ironing temperature.

She points out, “When you’re purchasing this equipment, for example, if you’re a hotel laundry looking to buy a new ironing machine, you need to know the laundry’s steam pressure.

If the pressure is only 5 or 6 bar instead of 8 bar or higher, this will affect your ironing speed and output, and this factor will also determine what type of ironing machine you should purchase.”

Leber also believes that the laundry must ensure an adequate amount of steam is continuously supplied to the ironing machine. Condensation will build up, so regular cleaning and maintenance of the steam traps are essential.

The steam traps are where the laundry’s steam ironing machine loses heat, and ultimately affects its productivity.

Similarly, laundry plants need to ensure all steam and condensate lines are insulated to minimize energy loss.

She said, “Depending on the distance between the ironing machine and the boiler, a significant amount of energy (temperature and heat) can be lost over that distance alone.

The longer the distance, the more important it is to ensure the steam pipes are insulated and maintained.”

Additionally, regularly check the pipes for leaks. Even small leaks can add up if multiple ironing machines are operating daily.

Ironing machines are typically heated by either steam, thermal oil, or direct natural gas combustion. Thermal oil-heated ironing machines use thermal oil for heating, which can be supplied by a boiler, self-heating (i.e., integrated thermal oil ironing machines), or, like steam ironing machines, heated by a thermal oil boiler.

Generally speaking, integrated ironing machines require less maintenance and do not need a boiler certificate.

Some call this a fully integrated system. An integrated ironing system heats the heat transfer oil in a heat exchanger, then the hot oil is drawn into the ironing bed of the ironing machine, and then returns to the burner for reheating, and the cycle repeats.

Like steam, the condensate returns to the boiler for reheating before returning to the ironing machine.

Leber suggests that laundry shops consult the manufacturer about the type of heat transfer oil used in their ironing machines, as there are many types. Different heat transfer oils have different viscosities and require different cleaning agents.

If the manufacturer’s recommended heat transfer oil is not used, laundry shops may encounter problems such as ironing bed clogging, decreased productivity, and slow heating. Heat transfer oil ironing machines can be heated remotely (by a boiler) or independently.

The key to ironing is using different temperatures for different types of linens. She said, “The advantage of all these ironing machines is that they all have a temperature range.

When new linens are put into use (whether owned, rented, or purchased by a customer), you should know the temperature range that the linens should withstand. What temperature can they withstand during washing, and what temperature can they withstand during drying and ironing?

This ensures that the linens are not only washed, dried, and ironed well, but also that the linens’ lifespan is ensured, thus reducing linen replacement costs.”

Several factors can contribute to poor linen quality when ironed by a laundry ironing machine. For trough ironing, one possible factor is wax buildup or over-waxing.

“You might be waxing the same spot repeatedly, causing wax buildup, and chemicals run to the edges of the ironing bed where linens aren’t being ironed,” says Leber. “This can result in accordion-like wrinkles on the ironed linens, as if the linens have been pricked in the ironing machine.

This is because the ironing bed surface isn’t smooth enough. An ironing bed is meant to be smooth and flat to produce high-quality linens. When there’s too much wax or a buildup of chemicals, the friction on the ironing bed increases, affecting both ironing quality and speed.”

To avoid this, she recommends cleaning the ironing bed surface daily with a clean cloth (running it several times on the ironing machine). The effectiveness of waxing varies from operator to operator, and sometimes the waxing results differ from day to day due to the varying number of linens being ironed.

She suggests, “A good practice is to wax the ironing press as soon as you start work, then wax it again at noon, and perhaps once more in the afternoon, depending on production volume.

Sometimes, when you see traces of wax, it means there’s wax buildup on the press. Sometimes waxing once a day is enough, but you should clean it daily with a cleaning cloth.” Regardless of the type of ironing machine used, always turn off the vacuum dehumidifier when waxing.

She says, “If you don’t turn off the vacuum dehumidifier, the ironing felt will become clogged with wax, and it will even draw wax into the pipes. You might also need to use a scouring pad to ensure the surface of the ironing press is clean and smooth.” She recommends waxing for about 3 hours a day. Don’t use too much wax, but wax frequently. To ensure the waxed cloth is clean and tidy, fold it neatly and place it on a rack after it cools down.

She said, “I don’t know if you’ve ever tried picking up a waxing cloth that’s been carelessly tossed aside; you’ll find it’s very stiff. They’re made of thick cotton cloth.

After the wax dries and cools, the waxing cloth becomes very stiff, making it difficult to use. I dare say operators need something easy to use. Good habits are needed when waxing. For ironing machines, proper maintenance is essential.”

Finally, the right temperature is also crucial for proper waxing.

She said, “If the temperature isn’t high enough, the wax won’t melt and won’t smooth the ironing bed. This doesn’t help iron the linens at all; in fact, it will leave the linens sticky with wax.”

Besides using scouring pads regularly, laundry plants must also thoroughly clean their ironing machines annually. For thorough cleaning, wrap a scouring pad around the rollers and run it across the ironing machine for half an hour, cleaning from one side to the other.

When waxing, always use a waxing cloth; do not apply wax directly to the ironing machine. The waxing cloth has a bag for wax paste or powder.

If you feel you’ve applied too much wax, it’s recommended to run a worn-out or discarded sheet or tablecloth across the ironing machine several times to absorb the excess wax.

Of course, in China, many laundry plants using trough irons still try to save money by skipping waxing, which leads to a decrease in ironing quality and efficiency, ultimately increasing costs.

Assuming the ironing board is very clean and waxed, pressure is perhaps the most important factor in ironing linens smoothly. This pressure comes from the roller springs and the felt padding.

If the ironer padding is worn, its contact with the ironing bed will be poor. Poor contact makes it difficult to iron the linens sandwiched between them smoothly. Therefore, regular replacement of the ironer padding is crucial.

Consult the manual or ask your supplier how often the ironer padding should be replaced. Additionally, the type of felt padding must be correct. Currently, there are generally two types of ironer padding on the market: polyester ironer padding and Nomex ironer padding (aramid 1313). The choice depends on the ironing machine’s temperature. Polyester felt padding can be used at temperatures below 185°C. Higher temperatures require aramid 1313 felt padding, as it can withstand higher temperatures.

Because the thickness and weight of the felt padding also vary, consult the manual or ask the manufacturer when replacing it.

Like the felt padding, springs are also wrapped around the ironing machine rollers. Springs can be individual or interconnected.

Leber says, “The springs’ role is to apply consistent pressure to the linens. This pressure is essential. The springs also help remove moisture from the linens. The small holes on the rollers are the escape routes for moisture from the linens.

So maintaining the springs properly is very helpful for dehumidification.

Vacuum dehumidification draws moisture from the linens through the small holes on the rollers, the springs, and the felt lining, and then out through the machine’s exhaust pipe. It’s important to ensure the vacuum fan is working properly and that the exhaust pipe and ventilation system are clean.

She suggests, “Whenever possible, make sure the ironing machine’s exhaust pipe runs vertically through the roof. Avoid bends as much as possible to minimize back pressure and reduce suction at the end.”

“If the linens aren’t dry enough after ironing and the dehumidification suction isn’t strong, then after checking the vacuum dehumidification, the exhaust pipe is also something to check. If the exhaust pipe has too many bends, wax can sometimes accumulate there, which will definitely negatively impact moisture removal.”

Regular maintenance of ironing machines is essential.

Generally, regardless of the type of ironing machine, laundry facilities should lubricate the machine and inspect the ironer belt and guide tape. Some ironing machines use scrapers instead of polyester ironer belts to guide the linens away from the rollers; these scrapers must be maintained.

Additionally, laundry facilities must dust the ironing machines.

Leber cautions, “I’m serious when I say ‘dust removal.’ I know that the first thing everyone does when they start work is blow away lint and dust. But when dusting an ironing machine, you must not blow dirt into the machine.”

“What I often see is us taking the air compressor’s exhaust hose and walking around the factory, blowing air onto the floor, the racks, and even under the ironing machines.

Blowing from under the ironing machine is fine. But blowing air onto the sensors, blowing air into the control box on the side, and things like that, is really not good practice.”

Leber recommends using a vacuum cleaner to clean the inside of the control panel, as well as the controller, sensors, and other sensitive components, to prevent dust and lint from being blown into the machine. Blowing lint into the machine can lead to long-term maintenance problems, and more seriously, it could cause a fire.

She says, “Sometimes we overthink cleaning the machine. Sometimes simple methods work. I once saw a laundry factory use a rope to remove lint from the conveyor belts, and then clean the rope from time to time.

They cleaned the belts like this every day. This method is simple, but convenient and practical.” Leber suggests checking several aspects of the ironing machine daily, starting with a safety check.

This includes ensuring the emergency stop button is working properly; that the safety shutters are not only working properly but have not been adjusted; and that the door locks, panel locks, and other parts of the machine are all in good working order.

She said, “Besides that, you should also look for alarm signals, especially when your machine is still new.

Of course, this is a bit tricky for older machines. If you know your machine well, you might as well listen to it and see if the sound is the same as when it’s running normally.

New machines usually have a touchscreen that displays alarms, indicating that the inverter needs to be reset or indicating where the problem is, etc. Pay close attention to the information displayed on the machine; modern machines are becoming increasingly intelligent.”

Daily inspection and maintenance also includes checking the felt padding, feed belt, and discharge belt. It’s also necessary to check for leaks, whether steam leaks, air leaks, oil leaks, etc.

Because these inspections and maintenance can reduce downtime and ensure that the ironing machine’s temperature remains normal, it’s essential to do this kind of inspection and maintenance.

During the weekly inspection and maintenance, clean all fans, check the gearbox, hydraulic pump, and the oil level in the heat transfer oil tank. Also, check the steam traps to see if they are working properly and ensure there is no condensation buildup. Clean the baffle connections on the inverter and the electrical box.

Leber points out, “Make sure the machine is free of dust, lint, etc. These can affect production or cause a fire. Also, ensure the burner and gas valve assembly are clean. Most of the time, the burner and gas valve assembly is separate from the machine.”

During monthly inspections and maintenance, check the heat exchanger, seals, chain tension, carbon brushes, grease chain, grease fittings, and gearbox plugs. Additionally, regularly add gearbox oil according to the equipment manufacturer’s requirements, and check the boiler and its licenses to ensure proper boiler operation, thereby ensuring the ironing machine receives the necessary steam for normal ironing operation.

Leber concludes, “Always use the right oil, felt padding, and springs. Don’t ignore or compromise on the manufacturer’s recommended inspection and maintenance items. They are mechanical experts who want you to achieve greater success while using their equipment effectively.”

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The aluminum extrusion machine is the leading equipment for the production of aluminum profiles. ...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

What is Nomex? Meta-amide, or meta-phenylene isophthalamide, is made from meta-phenylenediamine a...

Kevlar fiber Introduction In the development of materials science, Kevlar fiber has particularly ...