high temp Felt is mainly used on run-out tables, cooling beds, and conveying systems to protect hot aluminum profiles from scratches and deformation.

Typical operating temperature ranges from 180°C to 480°C, while extreme zones may require PBO felt up to ~600°C. This article lists 10 well-known high-temperature felt brands to help buyers quickly shortlist suitable suppliers.

Based on our long-term observation of aluminum extrusion plants in Asia, the Middle East, and Europe, felt performance is most critical at the following stages:

In practice, manufacturers often use different felt materials on different zones of the same line, balancing temperature resistance, service life, and cost efficiency.

|

Establishment: |

1968 |

|

Headquarters: |

Germany |

|

Website: |

BWF Group is a leading global manufacturer of industrial filtration materials. It primarily serves high-temperature industries such as aluminum extrusion, steel, and cement.

Its high temp Felt products, including felt rollers, felt belts, and felt pads, are heat-resistant and scratch-resistant, suitable for use in automated production lines.

BWF’s products are exported worldwide and used by many medium- and large-scale aluminum processing plants.

|

Establishment: |

1993 |

|

Headquarters: |

USA |

|

Website: |

https://www.miprcorp.com/ |

MIPR is a well-known conveyor belt manufacturer in the United States. The company produces a wide range of conveyor belt types, including rubber belts, food-grade belts, metal mesh belts, and high-temperature belts.

Some of its belts, such as Kevlar and Nomex, are specifically designed for use in aluminum extrusion processes. These belts are durable and tear-resistant, making them popular in aluminum extrusion production lines.

ECofill

|

Establishment: |

1983 |

|

Headquarters: |

USA |

|

Website: |

https://www.ecofill.com/ |

Ecofill is a US company specializing in the manufacture of high temp Felt. Its product range includes felt roller sleeves, endless belts, heat resistant pad, and felt covers, widely used in the aluminum extrusion industry.

Its Ecofill Needlefelt series offers excellent thermal stability and wear resistance, meeting the requirements for scratch-free conveying of aluminum profiles at high temperatures. It is suitable for various automated production lines and high-end surface treatment processes.

|

Establishment: |

1957 |

|

Headquarters: |

USA |

|

Website: |

Megadyne is a US company that manufactures timing belts, conveyor belts, and power systems.

These products are widely used in a variety of applications, including factories, packaging, food, transportation, and printing. In the aluminum extrusion sector, the company supplies belts for high-temperature and automated machinery.

These belts are durable, heat-resistant, and wear-resistant, and offer excellent synchronization. They are used in numerous factories worldwide.

|

Establishment: |

1988 |

|

Headquarters: |

South Korea |

|

Website: |

Bowoo Co. is a leading Korean manufacturer of high-temperature industrial felts, specializing in providing a wide range of heat-resistant conveying solutions for the aluminum extrusion, steel, and heat treatment industries.

Its high-temperature felt for aluminum extrusion is widely used in the cooling, conveying, and stacking stages of aluminum extrusion lines. Its excellent wear resistance and thermal stability make it suitable for a variety of automated production systems.

Bowoo products are widely recognized in the Asian market for their consistent quality and precise customization capabilities.

|

Establishment: |

1918 |

|

Headquarters: |

Japan |

|

Website: |

Ichikawa is a Japanese company that has been manufacturing industrial felts for a long time. They specialize in a variety of PBO and Para Aramid felts used in high-temperature conveying applications. These materials are used for aluminum extrusion production and provide excellent surface protection and heat resistance. This makes them suitable for automated processes that require high precision.

|

Establishment: |

2003 |

|

Headquarters: |

Thailand |

|

Website: |

https://www.filterdeperfect.com/ |

De Perfect is a professional manufacturer of industrial filtration and high temp felt in Thailand. Their products are widely used in the aluminum extrusion, steel, and other industries.

In aluminum profile production lines, their felt rollers, felt sleeves, and conveyor belts offer excellent heat and scratch resistance, making them suitable for high-temperature conveying applications and widely used in Southeast Asian markets.

|

Establishment: |

1992 |

|

Headquarters: |

Czech Republic |

|

Website: |

REKO sro is a renowned Czech supplier of industrial belts and conveyor systems, specializing in synchronous belts, flat belts, drive components, and customized conveying solutions. The company’s products serve a variety of industrial sectors, including packaging, logistics, food processing, and aluminum extrusion.

REKO offers a wide range of high-temperature-resistant synchronous and conveyor belts, ideal for the stable conveying of profiles from extrusion to cooling.

These belts offer wear and heat resistance, along with high-precision transmission, making them ideal for automated production lines and highly trusted by customers in the Central European market.

|

Establishment: |

1998 |

|

Headquarters: |

Türkiye |

|

Website: |

https://www.ozdemirkece.com/en/ |

Özdemir Keçe is a leading industrial felt manufacturer in Turkey, offering a full range of high temp Felt products for the aluminum extrusion sector, including roller felts, felt belts, gaskets, and sleeves.

These products offer excellent heat resistance and scratch-free conveying performance, making them widely suitable for automated production lines.

|

Establishment: |

1982 |

|

Headquarters: |

Hungary |

|

Website: |

https://bervina.com/ |

Bervina is a Hungarian manufacturer of precision transmission and conveyor systems, specializing in the production of high-quality polyurethane timing belts, couplings, and related custom accessories.

Its products are widely used in automation equipment, packaging, food, pharmaceutical, and light industrial conveyor lines.

They offer wear resistance, low noise levels, and high precision, serving customers across Europe, America, and Asia.

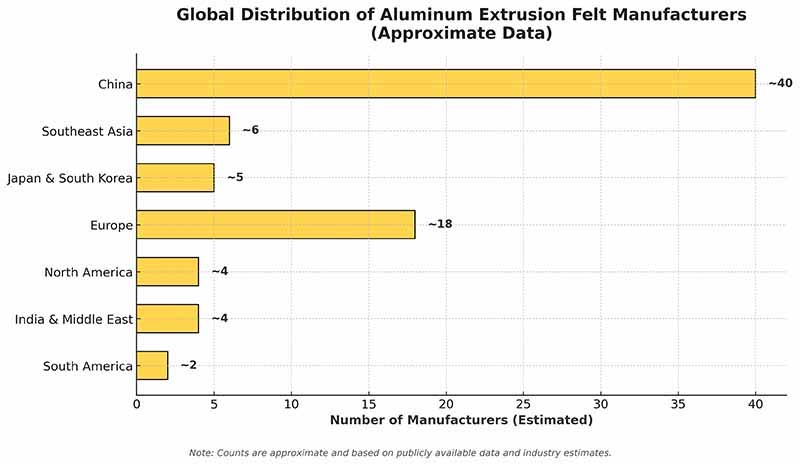

In addition to the top ten well-known brands introduced above, there are also a large number of small and medium-sized manufacturers active in the high temp Felt industry around the world. We have roughly sorted out other global aluminum profile high-temperature felt manufacturers by region.

China is the world’s largest manufacturer of high temp Felt, boasting a concentration of over 40 specialized manufacturers.

Among these, Pure Technology is a leading Chinese manufacturer of high temp Felt. Its product line includes felt roller, endless belt, and felt pad, which are widely used in cooling and conveying aluminum extrusions after extrusion.

The company emphasizes export quality control, with products exported to Europe, America, Southeast Asia, and other countries and regions. The company is committed to providing customers with stable, cost-effective conveying solutions.

There are approximately 5-8 manufacturers in Southeast Asia. Some companies in Thailand, Vietnam, Malaysia and other places have local production capabilities and mainly serve the Southeast Asian aluminum processing market.

Some also undertake processing for European, American, or Chinese brands.

There are about 4-6 Japanese and Korean manufacturers in total. Japanese and Korean manufacturers are known for their technology and high brand reputation. Their products are mostly used in high-end automated production lines, but the number of brands is relatively small.

In addition to the Top brand, there are still 15-20 manufacturers in countries such as Germany, Italy, the Czech Republic, Turkey, and Hungary that provide high temp Felt or synchronous belt products, mainly focusing on high quality and customized services.

Suppliers in the United States and Canada are mostly conveying system companies. There are only about 3-5 companies that produce their felt. Some brands mainly purchase European felt materials and then carry out deep processing.

There are approximately three to five manufacturers in India and the Middle East.

India’s manufacturing industry has grown rapidly in recent years, and a number of industrial felt manufacturers have emerged to serve local aluminum processing companies, though the quality varies. In the Middle East, the main focus is on agency and transit services.

There are only a few manufacturers in South America, with most relying on imports. In Brazil and Argentina, there are a handful of local manufacturers that provide basic products to regional customers.

Brands such as BWF, Ecofill, and Pure Technology have stable supply and after-sales systems in the international market and can provide both standardized and customized support.

Choosing a manufacturer with independent processing and inventory capabilities can help reduce delivery cycles and improve the efficiency of responding to emergency orders or replacing parts.

Low-priced products may sacrifice heat resistance or lifespan, leading to frequent replacements and potential scratching. Cost per unit lifespan and equipment compatibility should be considered comprehensively.

One of our customers in Thailand switched from standard felt belts to Nomex felt belt, extending replacement cycles by 30% and significantly reducing costs.

Regardless of the size of the brand, it is recommended to request samples for production line testing before formal bulk purchase to evaluate whether they meet the company’s temperature, tension, and surface protection requirements.

International brands such as BWF and Ecofill offer stable quality and long lifespan, making them suitable for high-end automated production lines.

Domestic brands offer advantages in terms of cost-effectiveness and delivery time. We recommend choosing the right brand based on your production line requirements.

You can ask the other party to provide real photos or videos of the factory, provide export qualifications and patent certificates, and check the ability to control product details. If you have a high-value order, you can personally inspect the factory for review.

It is recommended to give priority to brands with independent production, inventory management, and export experience, and to specify contract details such as delivery time, warranty terms, after-sales contact person, etc.

Yes—most manufacturers support customization of thickness, width, and joining methods; always confirm tolerance and temperature zone first.

This depends on production needs, budget, and quality requirements.

If you value stable production lines and excellent global service, consider well-known international brands like BWF and Ecofill.

If you’re looking for reasonable pricing, fast delivery, and custom sizes, brands like Pure Technology and Özdemir might be better choices.

If your profile surface requirement is high (anodizing/powder coating), choose felt with low shedding + stable density.

If you have frequent emergency replacements, prioritize suppliers with stock + fast lead time.

Choosing the best high temp Felt brand depends on a comprehensive consideration of heat resistance, product protection, delivery time, and price.

About the author: The author team is from Foshan Pure Technology Co., Ltd. We may mention our own products when discussing the China supplier landscape. All brands are described using the same evaluation criteria, and readers should always run sample tests before placing bulk orders.

As we know, Heat Transfer Printing Felt is suitable for fabrics, decorative fabrics, curtains, le...

Read Safety Rules for Laundry Management to be a qualified manager. PARTⅠ Laundry room Safety Gen...

The aluminum extrusion machine is the leading equipment for the production of aluminum profiles. ...

Heat transfer printing is a contemporary printing process in the clothing market. It prints the p...

In the textile industry, felt is only a small part but important. About how to choose felt that i...

Foshan Pure Technology Company., Ltd. helps conveyor belt manufacturers source equipment to metal...

What is Nomex? Meta-amide, or meta-phenylene isophthalamide, is made from meta-phenylenediamine a...

Kevlar fiber Introduction In the development of materials science, Kevlar fiber has particularly ...